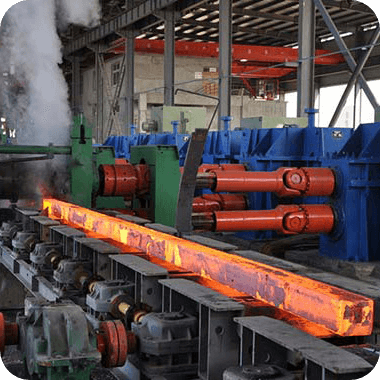

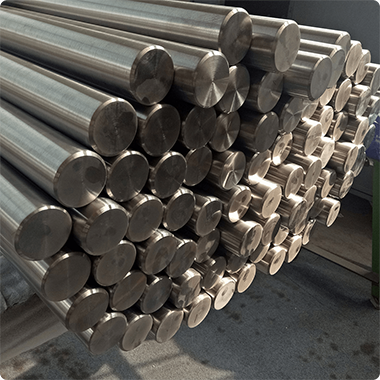

Hele Titanium stands as one of China’s foremost suppliers of titanium pipes and tubing. With over a decade in the industry, our expertise guarantees both standard and tailor-made solutions to meet diverse requirements. Reach out to us today and discover the Hele Titanium difference for all your titanium tubing needs.

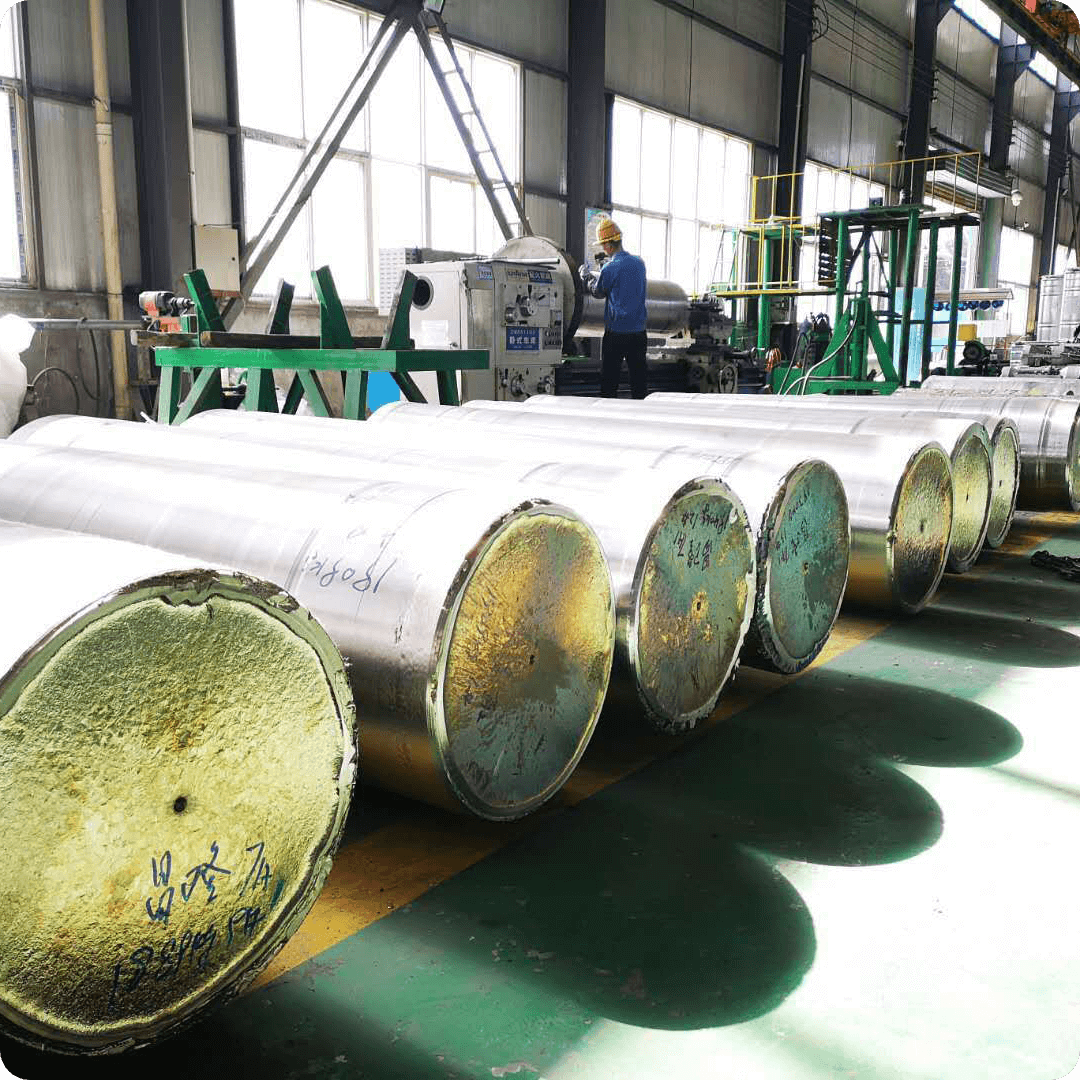

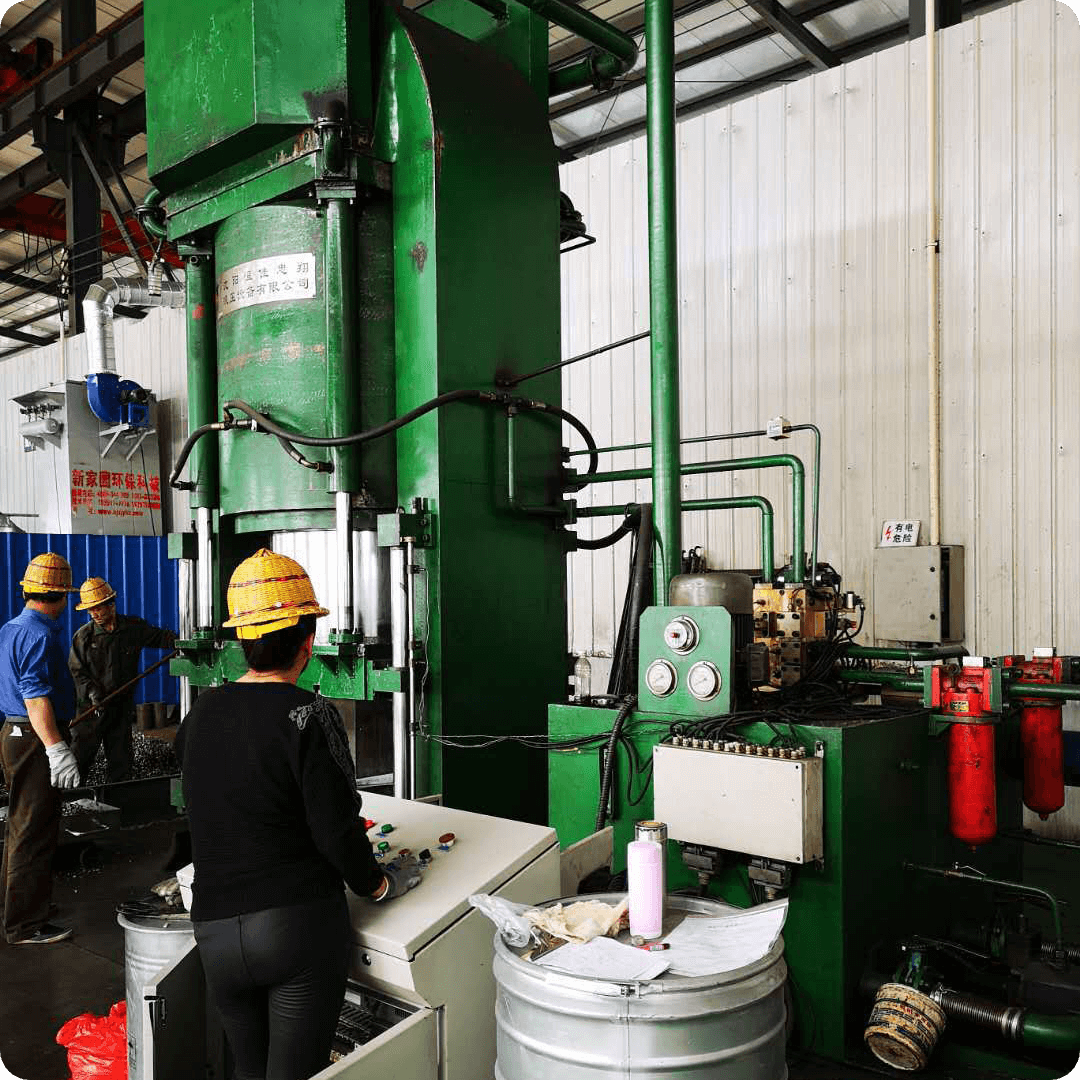

Our Customization Service Includes:

Our Customization Service Includes: