Your Trusted Partner for Streamlining Medical Supply Chains

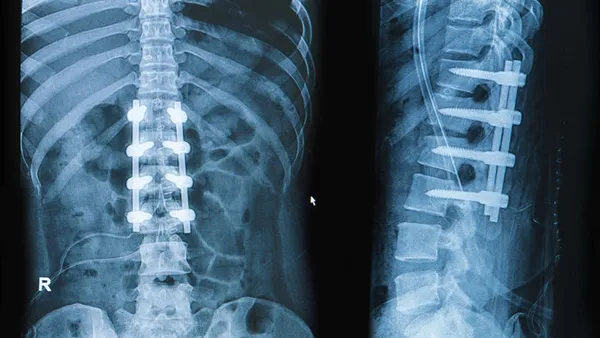

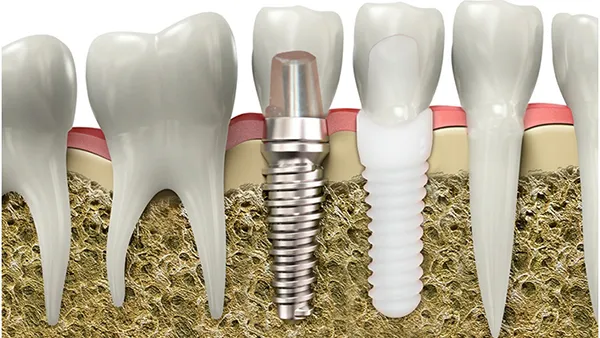

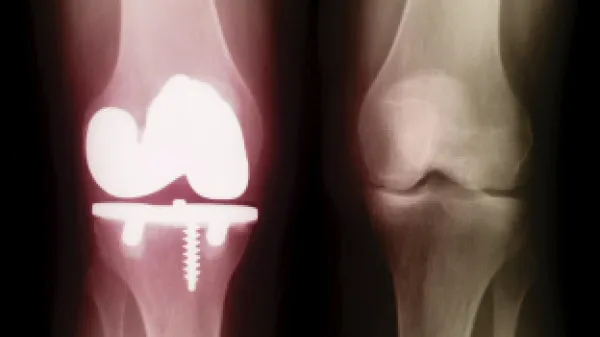

With a decade of expertise in the titanium industry, Hele Titanium provides medical device manufacturers with a comprehensive range of high-quality grades and services, particularly for dental and orthopaedic implants, spinal fixation, soft tissue repair, bone screws, trauma plates, and other medical applications.

Our primary biocompatible titanium grades for orthopaedic, trauma and vascular prostheses and implants are as follows:

| Grades |

International Standards |

Available Shapes |

| Ti 6Al-4V ELI Grade 23 |

ASTM F136 – ASTM F1472 – ISO 5832-3 |

Bar/Sheet/Power/Wire |

| Ti Grade 2 |

ASTM F67-ISO 5832-2 |

| Ti Grade 4 |

ASTM F67-ISO 5832-2 |

Our certifications in quality, safety, and the environment are evidence of our dedication and professionalism.

We offer:

- Optimal response time

- A specialized stock for the medical sector, with the option of delivery from available stock, no matter the quantity.

- A commitment to quality and traceability

- Value-added services (custom cutting, chamfering, custom stock management, etc.)

- Technical support

- Quick and efficient local service through an international logistics organization.

Customized Cutting Services

We have a dedicated automatic machine reserved specifically for the medical cutting industry.

Our Technical Capabilities:

- Sawing of bars and tubes with an outer diameter from 6mm to 320mm

- Sawing of flat bars (LxW): 10 x 8mm to 350 x 320mm

- Cut accuracy in accordance with DIN ISO 2768

- All medical grades, including small, medium, and large series.

Hele Titanium provides a comprehensive range of medical materials in the following forms: