In Summary

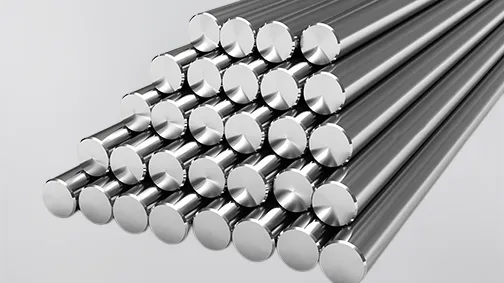

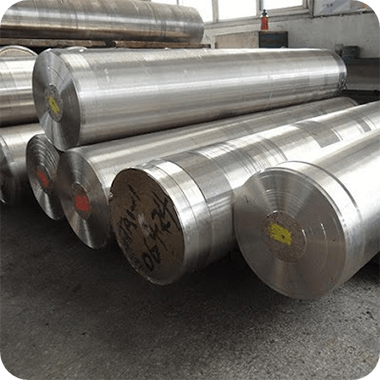

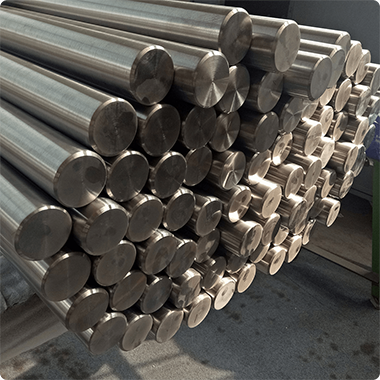

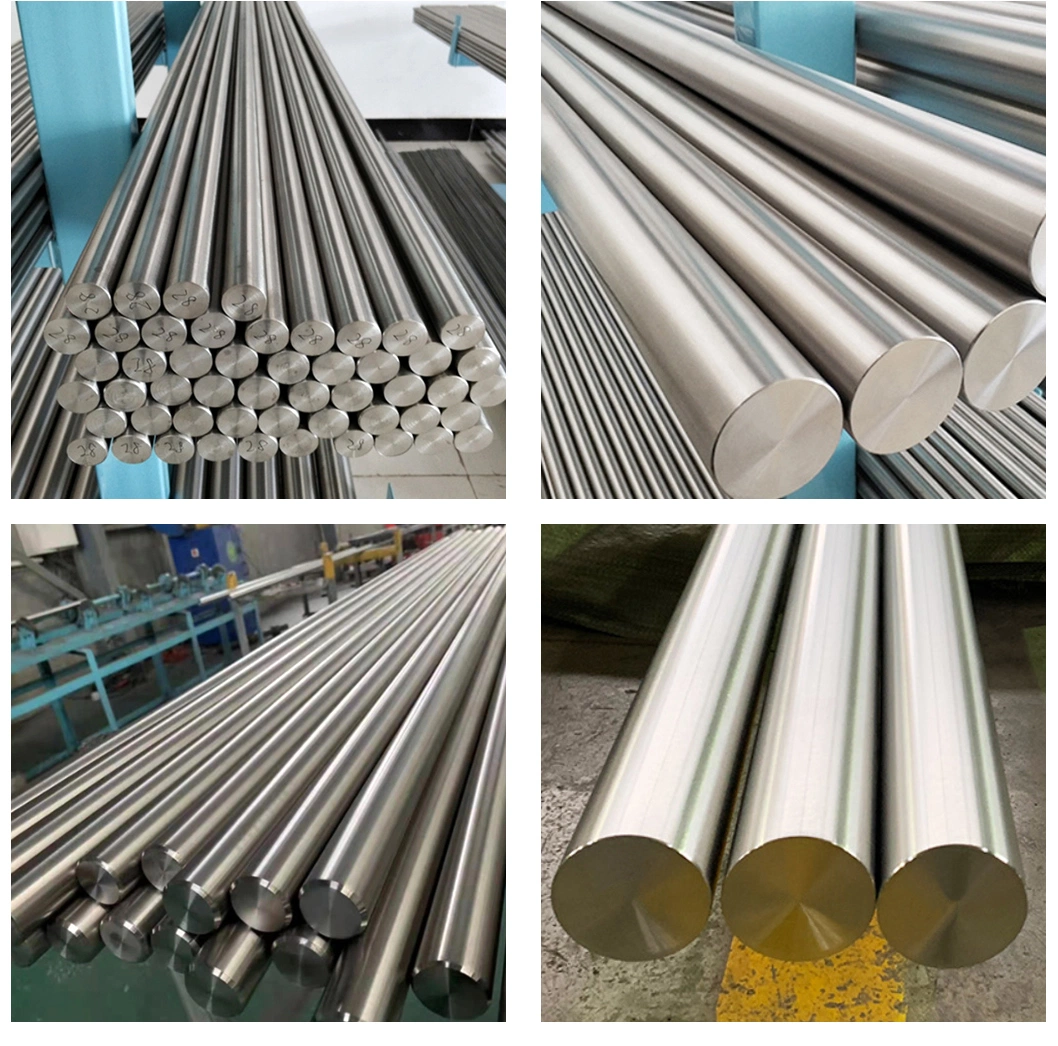

Titanium bars and rods, celebrated for their exceptional strength and resistance to corrosion, play a vital role in industries like aerospace, medical, and architecture. However, selecting the right titanium products can be a daunting task for new buyers.

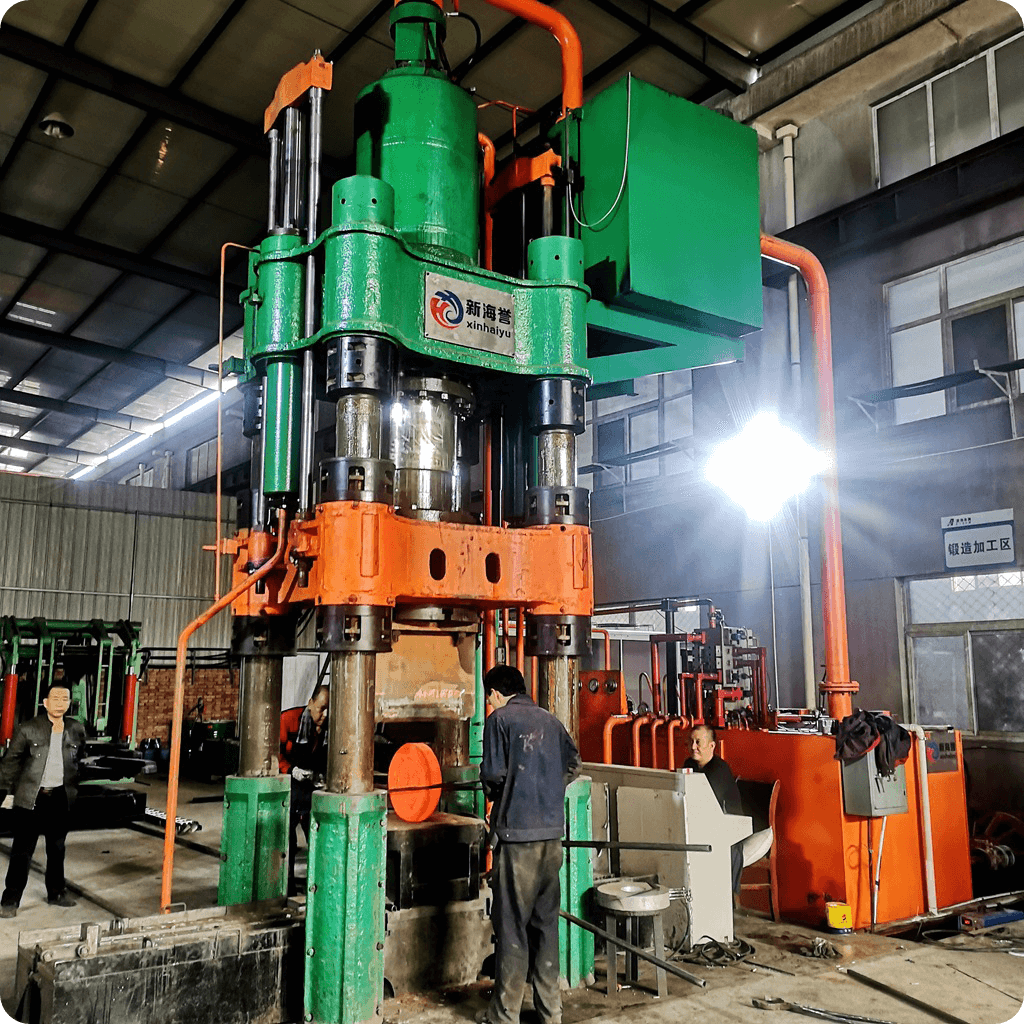

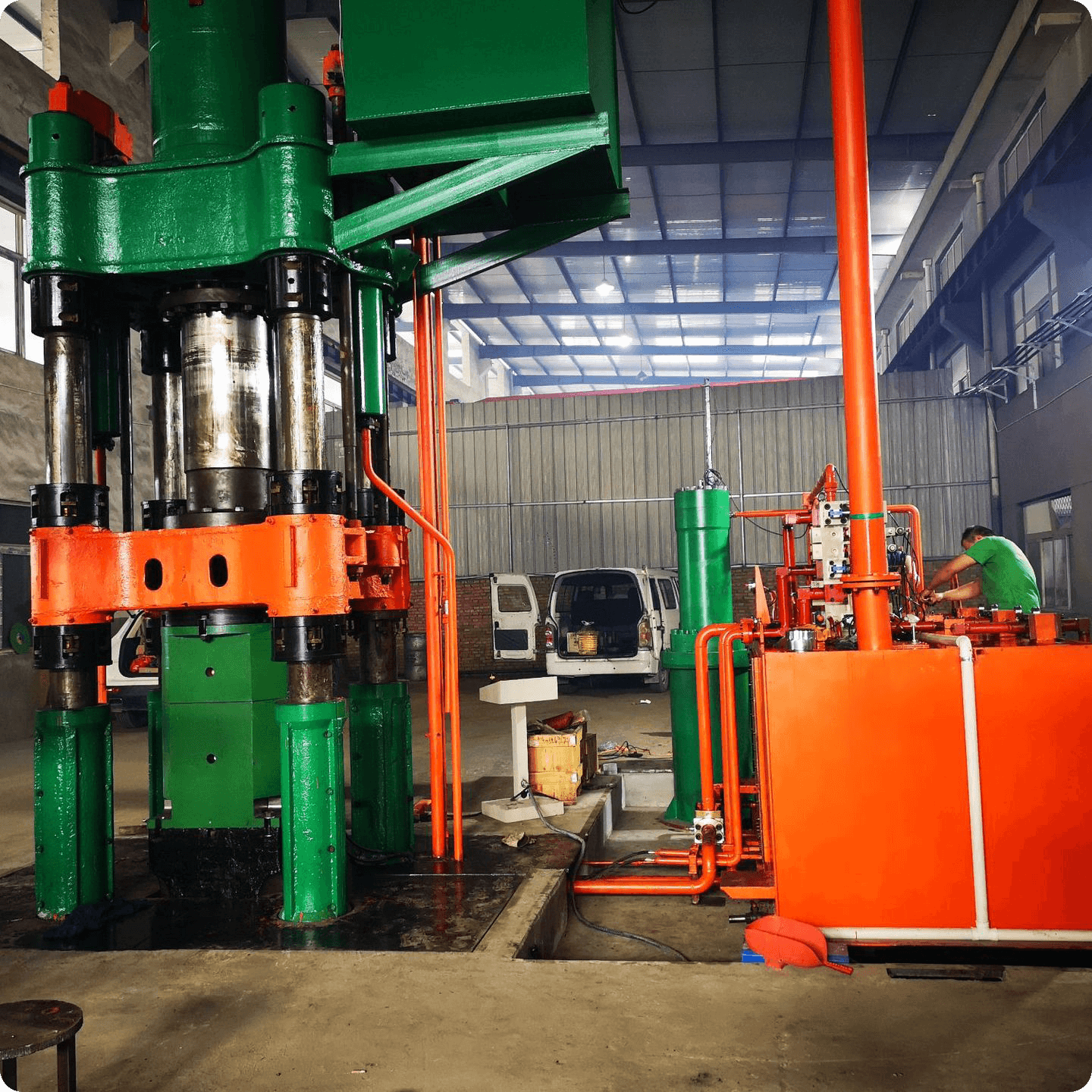

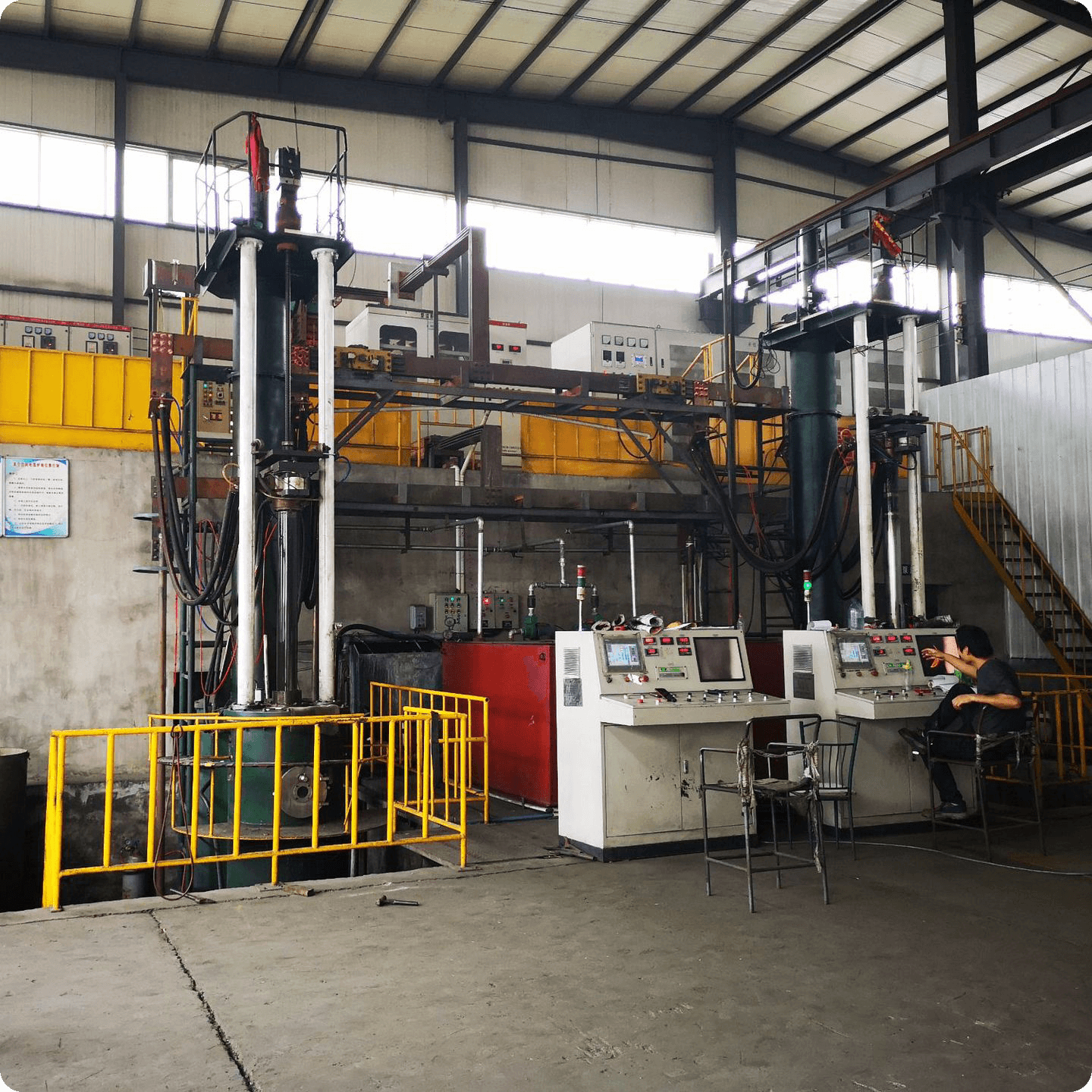

Hele Titanium, a renowned manufacturer, stands out as a trusted source for top-quality titanium bars and rods. Our comprehensive services guarantee precision at every step, from selection to delivery, making Hele Titanium the preferred choice for high-grade titanium needs.

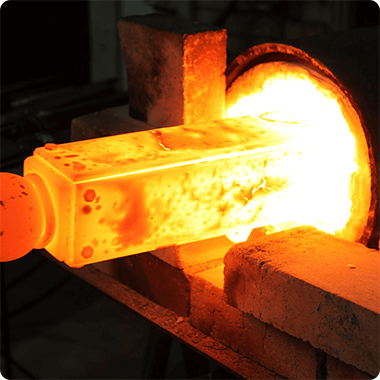

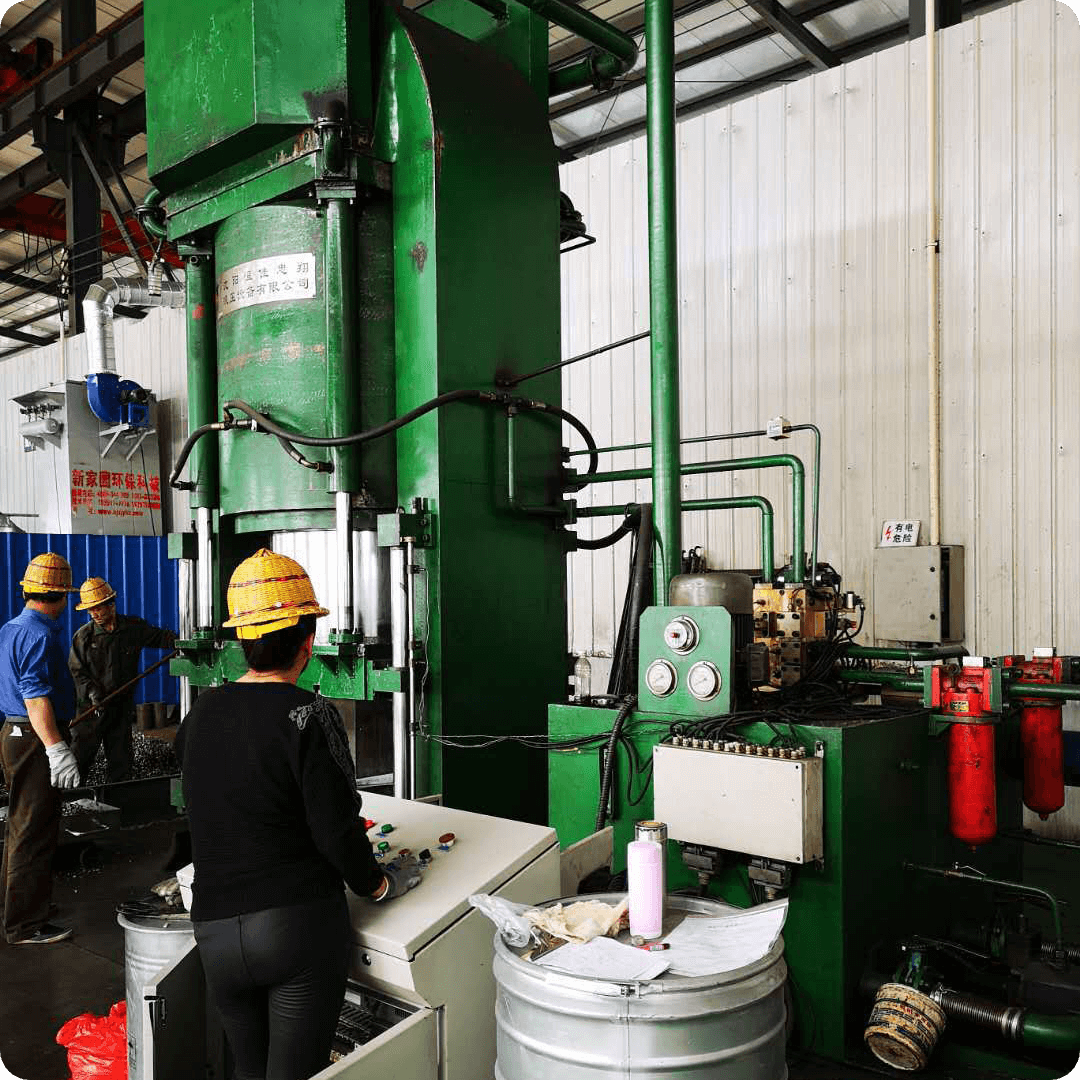

Moreover, we offer the flexibility to produce customized samples tailored to your exact specifications in most cases. This ensures that you receive the precise titanium bars and rods you require for your specific projects.

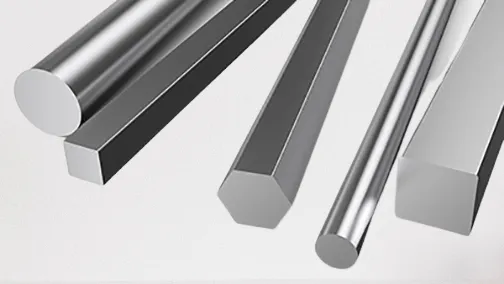

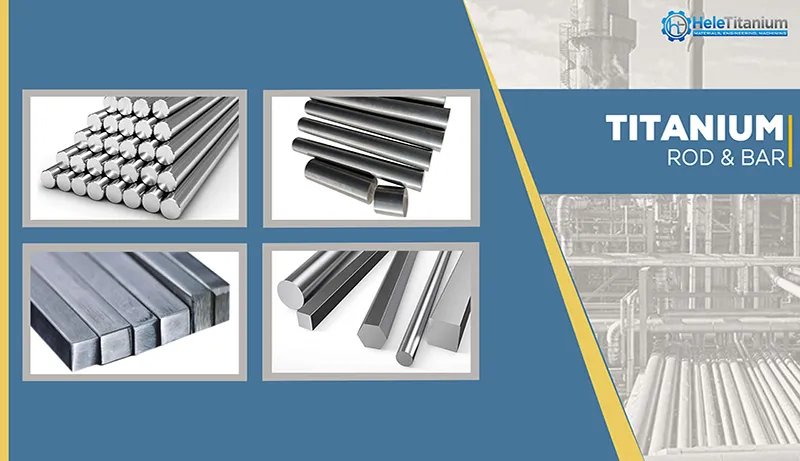

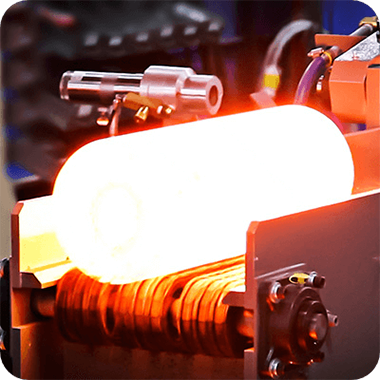

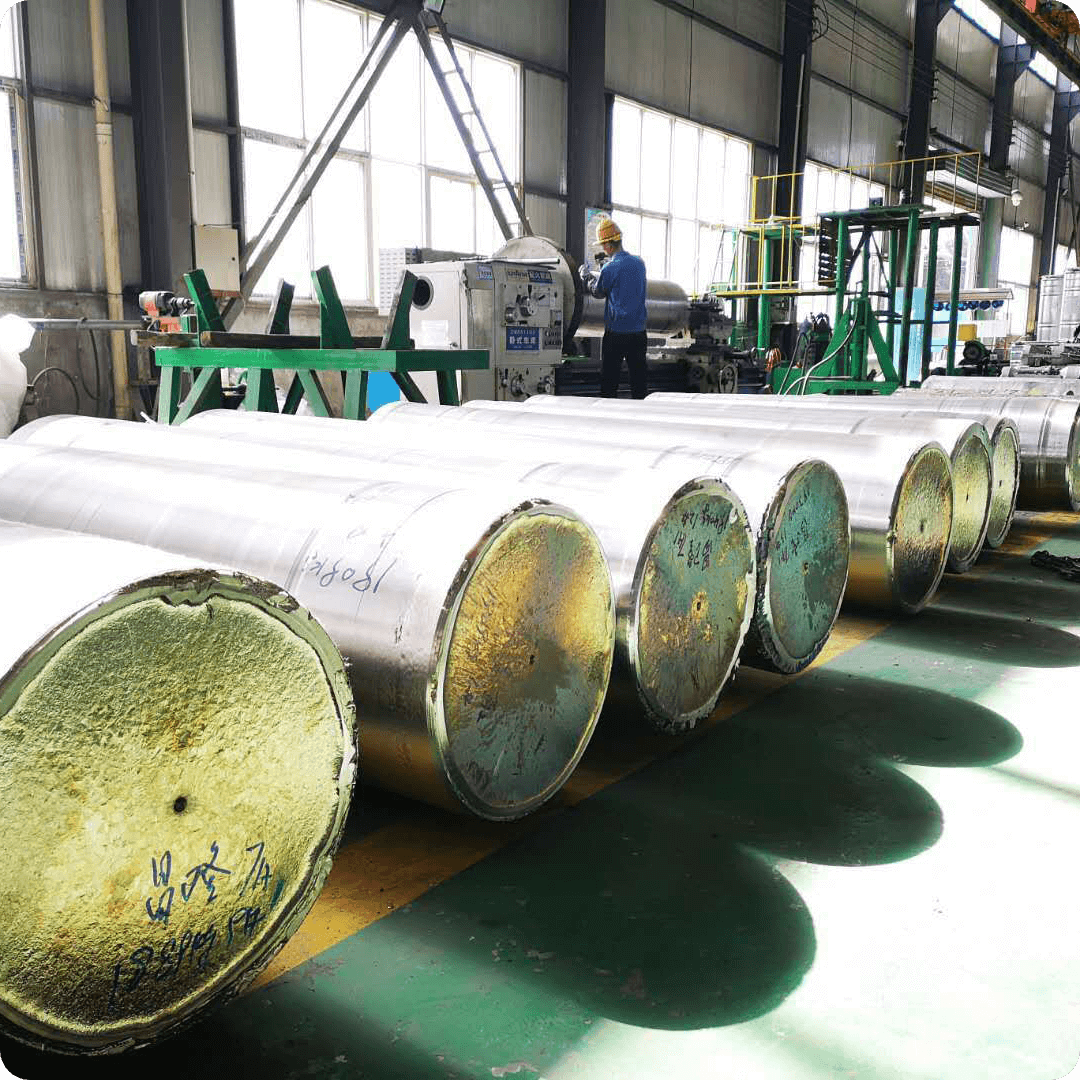

At Hele Titanium, we understand that various projects have distinct specifications and requirements. That’s why we offer a range of forms to cater to your precise needs. Here’s an overview of the different forms available for your specific applications:

At Hele Titanium, we understand that various projects have distinct specifications and requirements. That’s why we offer a range of forms to cater to your precise needs. Here’s an overview of the different forms available for your specific applications:

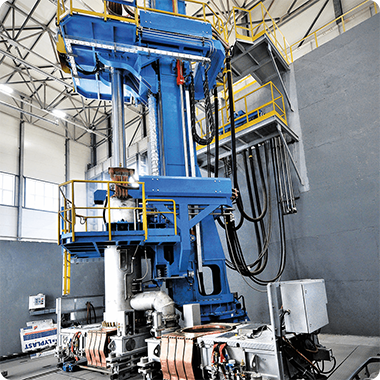

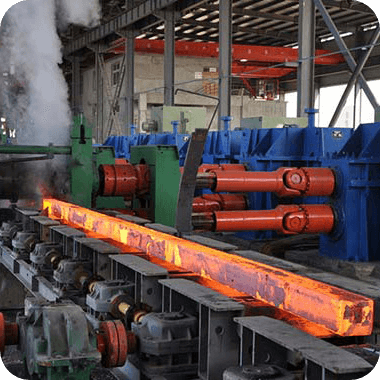

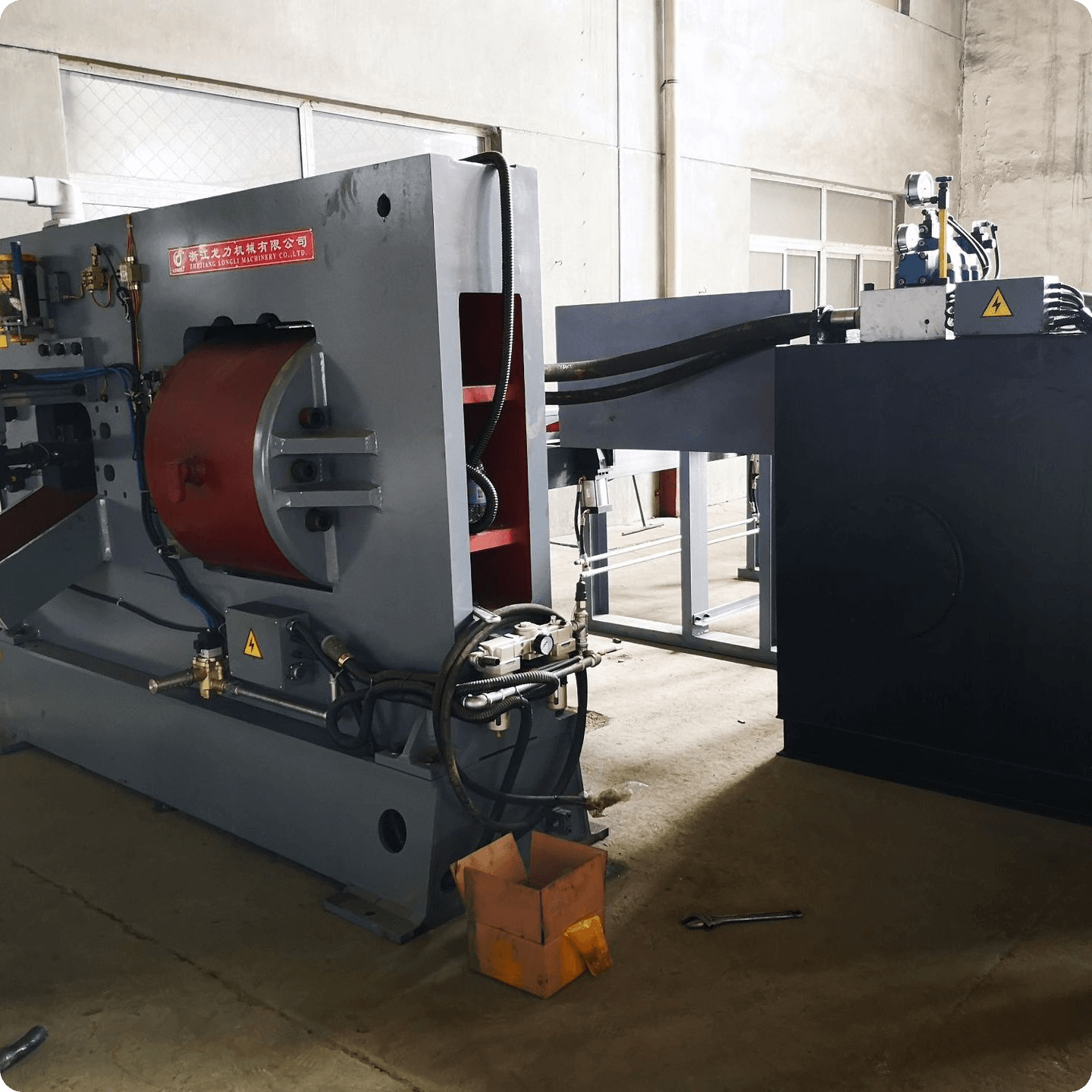

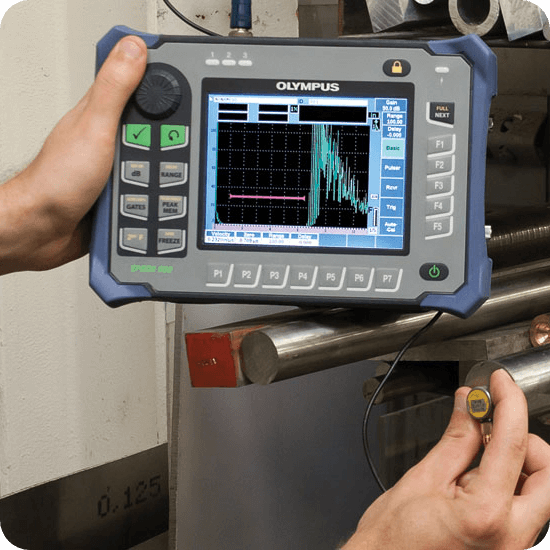

Experience: Opt for suppliers with a proven track record and extensive experience in the titanium industry. A supplier with a long history of successful operations is more likely to provide quality products and services.

Experience: Opt for suppliers with a proven track record and extensive experience in the titanium industry. A supplier with a long history of successful operations is more likely to provide quality products and services.