Seeking expansive, custom-fitted, or near-net-shape titanium solutions?

Seeking expansive, custom-fitted, or near-net-shape titanium solutions?

Hele Titanium specializes in crafting tubes, profiles, plates, sheets, and bars to meet nearly any requirement. With an array of well-maintained processing equipment, we guarantee complete industrial satisfaction.

Hele Titanium is poised to enhance your business through the following techniques and welcomes the opportunity to take on virtually any metal fabrication challenge.

Along with titanium-based offerings, our company provides expert welding services. This enables you to have your tools and components crafted from a range of metals, all welded to precision. The smooth, professionally finished edges of these tools and components will allow you to complete your projects efficiently.

Our welding services encompass four major techniques: GMAW/MIG (Gas Metal Arc Welding), GTAW/TIG (Gas Tungsten Arc Welding), SMAW (Shielded Metal Arc Welding), and FCAW (Flux Cored Arc Welding).

Our sheet metal shearing offerings allow you to receive pre-cut sheet metal for your operations. Equipped with state-of-the-art sheet shearing equipment, we guarantee a quick turnaround time for your finished sheets.

The specifications of our sheet metal shearing machine include:

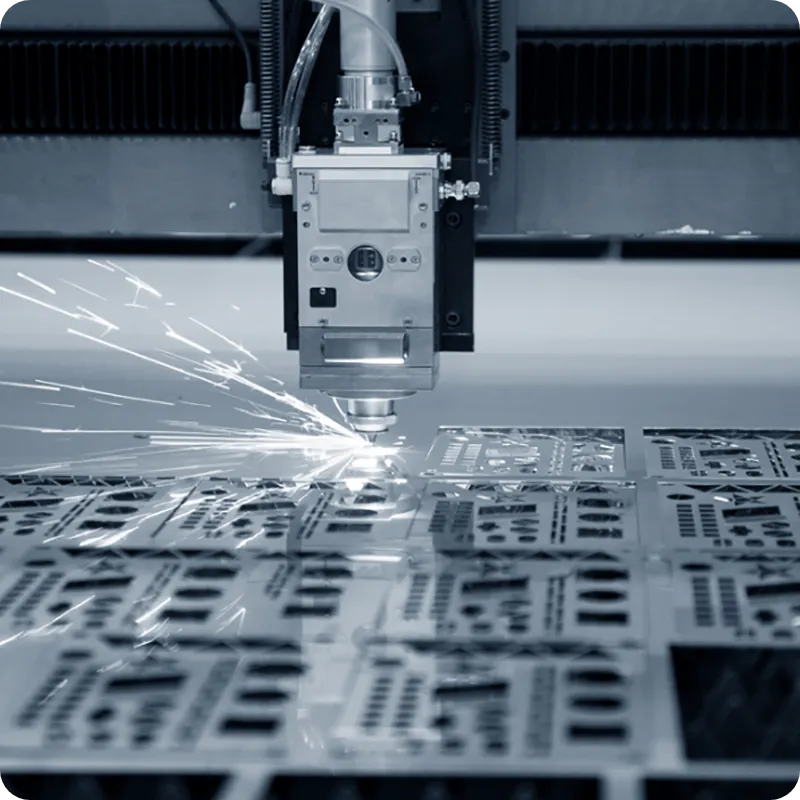

At our facility, we have installed a cutting-edge laser-cutting machine, offering our clients laser-cutting services for an array of metals. The selection of this high-performance machine was driven by its capability to deliver precise cuts, resulting in exceptional output. If you require metal laser cutting in any dimensions, shapes, or sizes, Hele Titanium is your go-to source.

The capabilities of our laser cutting machine are as follows:

Electron Beam Melting (EBM) is a cutting-edge additive manufacturing process used in the creation of various metal-based tools and components.

At Hele Titanium, we utilize this method to fabricate our products using titanium metal, ensuring that our customers receive the highest quality end products. The EBM process involves melting titanium layers with an electron beam to build up the final product, layer by layer. This method provides exceptional precision and accuracy, resulting in highly complex and intricate shapes that would be difficult to achieve with traditional manufacturing techniques.

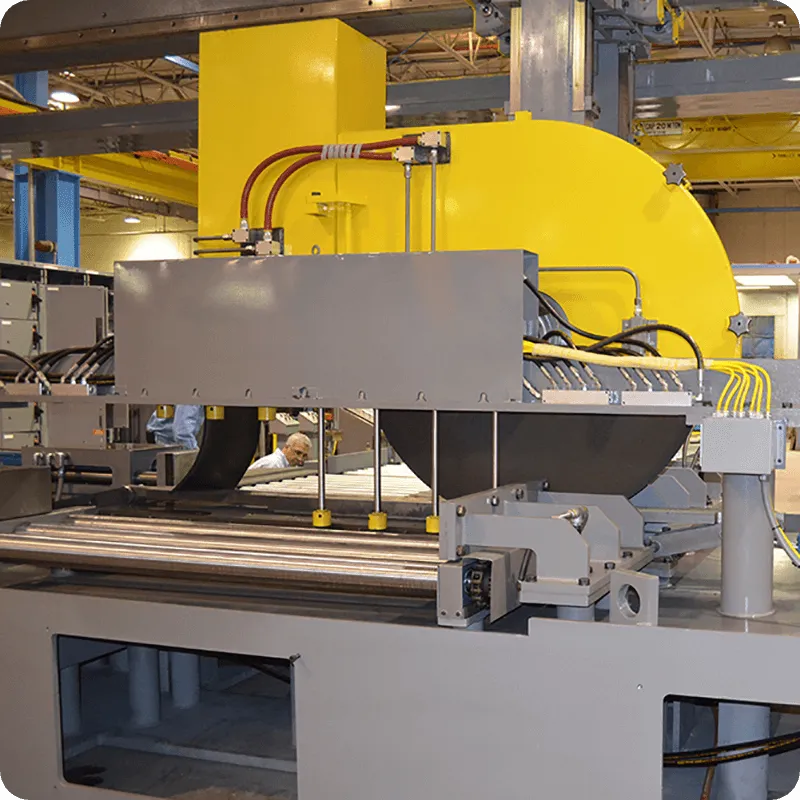

Metal stamping involves transforming metal sheets into a specified shape or design through the process of piercing or punching. At Hele Titanium, we provide this stamping service for all types of sheet metal to meet the needs of our customers.

Our metal stamping services include the following three technologies:

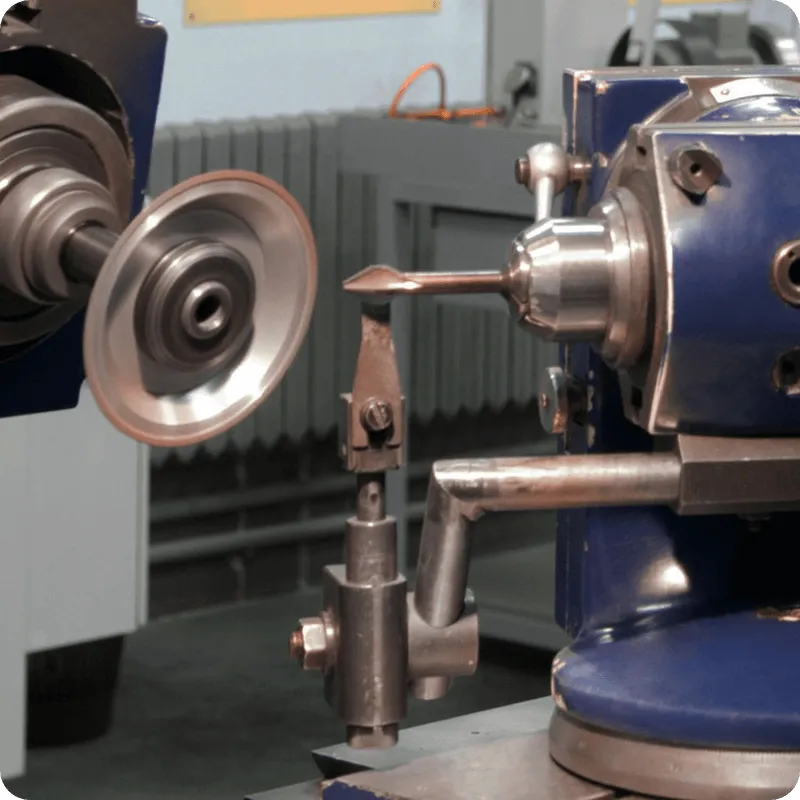

In addition to our services, we provide lathe machining capabilities that allow us to produce products in a range of shapes and sizes. Our lathe machine rotates the workpiece to create a custom-designed product to meet the customer’s specifications.

The capabilities of our turning machine are as follows:

Shape: Cylindrical with thin walls or solid cylindrical

Part size: Diameter ranging from 0.02 to 80 inches

Materials: Metal, Steel, Aluminum, Copper, Titanium, Zinc

Surface finishing: 16-25µin

Maximum wall thickness: 0.05-2.5 inches

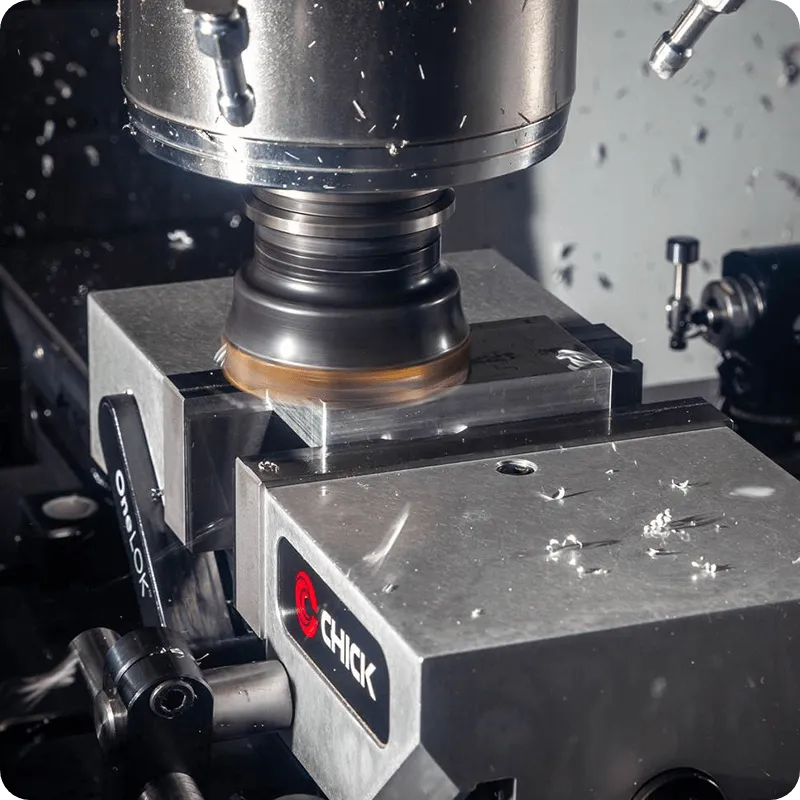

CNC machining services for titanium materials are also available at Hele Titanium and you can have high-precision CNC machined parts made to your specifications.

Our CNC machining capabilities include

Cutting is involved in the manufacture of various metal-based products, and we offer abrasive sawing services to cut down these parts to create the required tools.

Our abrasive sawing machining can be used for the following

Our saw-cutting services provide a range of titanium-based products that require cuts in various sizes and dimensions. With our cutting-edge sawing technology, we can meet all your sawing needs, ensuring that you receive the highest quality end product. So, when it comes to sawing, you can trust Hele Titanium to deliver exactly what you need.

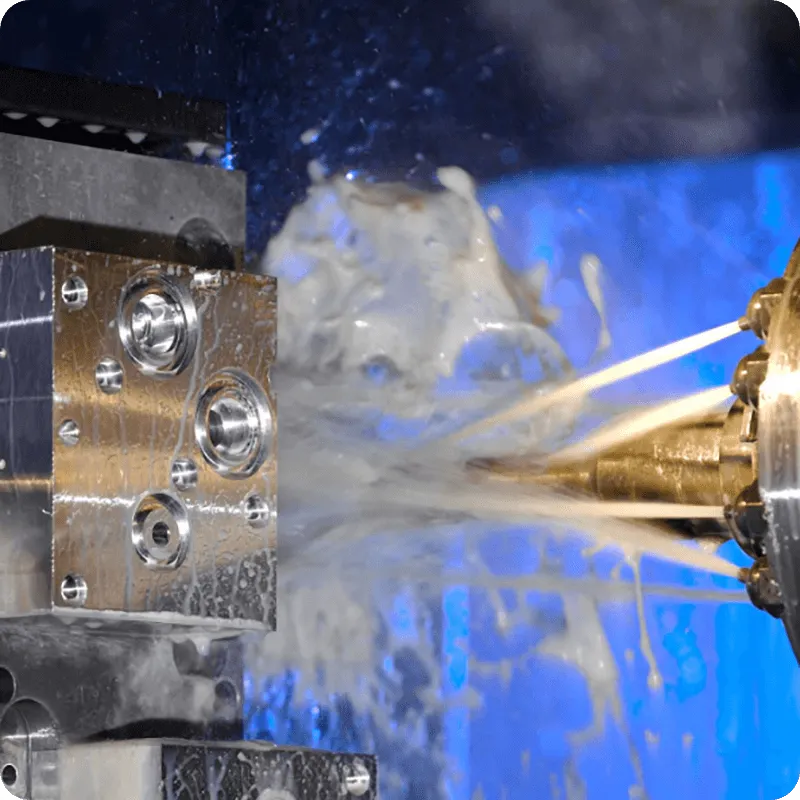

Water jet cutting is a highly effective method for cutting materials, such as titanium, that are sensitive to heat. At Hele Titanium, we use this cutting technology to ensure that your titanium-based products are not damaged during the cutting process, while still achieving the desired cutting results. Our water jet cutting services guarantee precisely shaped cuts for a variety of products.

Bending is an essential process in the creation of various products, allowing for the shaping of sheet metal into the desired form. At Hele Titanium, our bending services enable us to meet the unique requirements of our customers by providing a range of product shapes. Whether you need simple curves or complex shapes, our expert team is equipped to deliver the perfect bend for your product.

Our drilling services are specifically tailored to provide precision and accuracy when working with titanium material. Given that drilling can be a slightly aggressive process, it is crucial that it is performed with care, as titanium requires a delicate touch. At Hele Titanium, our extensive knowledge of titanium enables us to drill this material to perfection, ensuring that our customers receive the highest quality end product.

CNC milling is a comprehensive process that enables the creation of various metal-based products in a range of 2D and 3D shapes. At Hele Titanium, we offer CNC milling services to provide our customers with high-precision titanium components in any size and level of detail. Whether you need simple or complex designs, our advanced milling equipment and experienced team ensure that your components are manufactured to the highest standards.

When producing titanium products, some metal removal may be necessary to achieve the desired component shape. As titanium is a delicate material that requires a high level of care, our grinding services are designed to ensure that this care is taken. At Hele Titanium, we are committed to providing our customers with a result that makes choosing us a worthwhile investment. Our grinding services guarantee a precise, high-quality finish that meets all your manufacturing needs.

At Hele Titanium, we offer a full range of fabrication services for metal components. If you are in need of fabrication services for titanium metal, we are the team to turn to. Our experienced professionals are equipped to handle all the fabrication steps associated with this material, ensuring that your component is manufactured to your exact specifications, with all the necessary details included. Contact us today to learn more about how we can meet your fabrication needs.

Precision machining is an essential process for creating smaller components used in various applications that require intricate detail. This process encompasses a range of techniques, including CNC milling, turning, and machining. At Hele Titanium, we provide all of these precision machining services under one roof, ensuring that your smaller titanium components are manufactured to the highest standards. Whether you need precise cuts, intricate designs, or highly detailed components, our team of experts is equipped to deliver the precision machining solutions you require.

Shear cutting is a crucial process in the creation of metal components and products. This method involves cutting a sheet of metal to achieve a specific design or component shape. At Hele Titanium, we utilize titanium to manufacture elements that require shear cutting. With our advanced cutting technology and experienced team, we ensure that your titanium-based components are cut to your exact specifications, with precise accuracy and a high-quality finish.

Discover top-tier titanium artistry at Hele Titanium. From custom designs to near-net-shape products, our range includes everything from tubes to bars, all perfectly tailored to your needs.