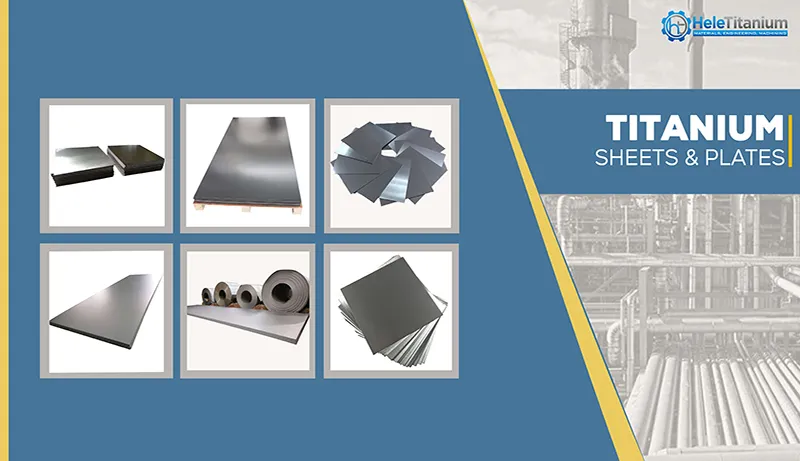

Titanium Plate/ Sheet Quality Standards

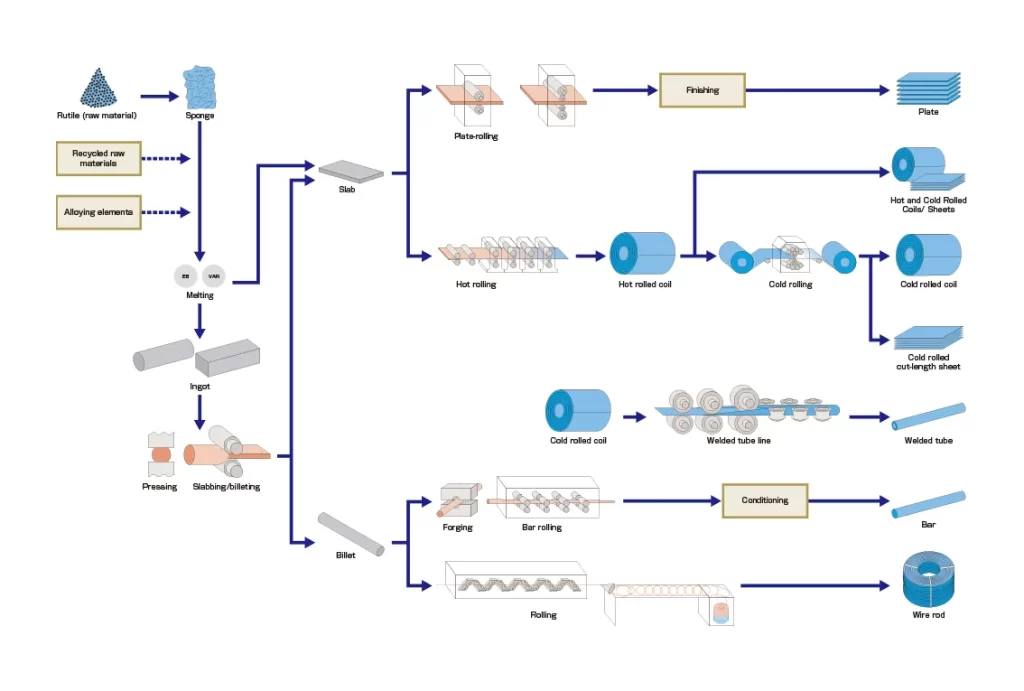

Titanium plates and sheets are meticulously crafted following stringent standards to ensure top-notch quality. Different regions have their established benchmarks, with China and the USA being predominant contributors.

China’s quality standards adhere to:

- GB/T3621-2007

- GB/T13810-2007

In contrast, the USA follows multiple standards such as:

- ASTM B265

- ASTM F136

- ASTM F67

- AMS 4928

For a clearer understanding, let’s break down these standards based on size, grade, and the exact standard reference:

| Size (mm) |

Grade |

Standard References |

| 0.5 to 100 |

6AL-4V, 6AL-4V ELI |

AMS-4911, 4907, 4905, MIL-T-9046, ASTM-F136 |

| – |

6AL-2SN-4ZR-2MO |

AMS 4919, MIL-T9046, DMS-2275, AMS-T-9046 |

| – |

6AL-6V-2SN |

AMS-4918, MIL-TT-9046, DMS-1879, AMS-T-9046 |

| – |

5AL-2.55N, 5-2.5 ELI |

AMS-4909, 4901, MIL-T-9046, AMS-T-9046 |

| – |

BAL-IMO-1V |

AMS-4915, 4916, DMS-1784 |

| – |

CP-Grades 1,2,3,4 |

AMS-4900, 4902, MIL-T-9046, AMS-T-9046, DMS-1536 |

These standards are a testament to the quality and precision in the production of titanium sheets and plates, ensuring they meet international demands and specifications.

Titanium plates and sheets are renowned for their combination of strength, corrosion resistance, and lightweight properties, making them indispensable in numerous sectors:

Titanium plates and sheets are renowned for their combination of strength, corrosion resistance, and lightweight properties, making them indispensable in numerous sectors: