Hele Titanium is a well-respected manufacturer of titanium electrolyzer cells, committed to offering the best salt & seawater electrochlorination solutions, tailored to meet your specific needs.

Hele Titanium is a well-respected manufacturer of titanium electrolyzer cells, committed to offering the best salt & seawater electrochlorination solutions, tailored to meet your specific needs.

Are you seeking a reliable and efficient supplier for your electro-chlorination project? Look no further than Hele Titanium. Drawing upon our extensive experience in producing titanium electrolytic cells in China, we offer decades of expertise in the realm of Mixed Metal Oxide (MMO) anodes. Our state-of-the-art manufacturing facilities and advanced proficiency enable us to produce premier electro-chlorination systems and plants, catering to various applications in brine and seawater.

Introducing an advanced Sodium Hypochlorite Electrolyzer – a water treatment solution that sets industry standards. Excel in sodium hypochlorite production with our efficient electrolyzers, ensuring reliable water disinfection in diverse applications.

Explore the Sodium Chloride Electrolyzer Cell, an advanced solution for efficient sodium chlorite production through electrolysis. Count on reliable, top-quality electrolyzer cells customized for various applications.

Discover the Seawater Sodium Hypochlorite Generator – your reliable on-site solution for producing potent disinfectant from seawater. Count on expertise for efficient and customized sodium hypochlorite generators.

Explore the Brine Water Sodium Hypochlorite Generator – the ideal on-site solution for creating powerful disinfectant from brine water. Rely on proficiency for effective and tailored sodium hypochlorite generation.

Explore the Titanium MMO Electrolyzer – your solution for efficient electrochemical processes. With expertise in MMO anode technology, high-quality systems cater to diverse needs.

Discover the Titanium Electrolyzer Cell – your solution for diverse electrochemical needs. Crafted with precision, these cells guarantee optimal efficiency and unwavering reliability.

Expertly crafted with two titanium tubes, specifically designed for electrolysis, and built to resist corrosive electrolytes, ensuring stability for optimal reactions. Primarily dedicated to water treatment applications.

Crafted with MMO titanium anodes, this electrolytic cell harnesses electrical energy to facilitate chemical transformations, making it a vital component in large-scale land-based water treatment applications.

Hele Titanium produces a diverse array of titanium electrolyzers, ensuring optimal efficiency for the electro-chlorination process and meeting rigorous industry standards. Our product range includes off-the-shelf and customized electrolyzers tailored to your needs, suitable for seawater and saltwater applications.

Our customization options include:

Our pride stems from our dedication to delivering timely assistance, maintaining rigorous quality standards, and providing customized electrochlorination solutions that perfectly align with our customers’ needs. These principles form the core of our growing reputation, establishing Hele Titanium as a frontrunner in the electrolysis cell industry.

Hele Titanium, a prominent manufacturer of titanium electrolyzers, specializes in electrochlorination systems for seawater and brine water. Whether you’re a wholesaler, brand owner, individual, laboratory, or contractor, we offer customized solutions to match your unique needs.

For Wholesalers: Tap into the advantages of our well-equipped electrolytic cell manufacturing. We offer high-quality products at competitive prices, empowering you to present irresistible deals to your clientele.

For Brand Owners: Partner with us as we lead businesses through the journey from concept to tailored electro-chlorination solutions for their production requirements, ensuring the triumph of their brand.

For Contractors: Make the most of our cutting-edge production facility to access top-tier options that resonate with your target audience. Depend on our streamlined manufacturing process for superior product offerings.

Titanium MMO electrolyzer cells have a wide range of uses, including chlorine production from brine and sea water, electrolytic disinfection equipment, sodium hypochlorite generators, and water treatment solutions. These cells are available in various sizes and styles to meet the specific requirements of different projects.

Whether you’re importing titanium electrolyzer cells for your Electrochlorination projects or considering wholesale distribution in your local market, this essential buyer’s guide provides you with all the information you need for a smooth purchasing experience.

Chapt 1

A Titanium Electrolyzer, also referred to as a Titanium Electrolytic Cell, is a specialized container that employs MMO titanium anodes to perform electrochlorination process.

This process converts saltwater or seawater into a disinfectant solution known as sodium hypochlorite.

These electrolyzers cells find widespread use in various applications, including electrolytic disinfection equipment, sodium hypochlorite generators, and within the water treatment industry wherever sodium hypochlorite based disinfection is needed.

Chapt 2

A Titanium Electrolyzer Cell is an essential component used in the electro-chlorination process. This process involves passing an electric current through salt water or an artificial brine solution using an electrode assembly.

During electrolysis, Sodium Hypochlorite is produced as the primary product, while hydrogen gas is generated as a by-product due to its lower density. The chemical reactions can be expressed as follows:

2 NaCl + 2 H2O → Cl2 + H2 + 2 NaOH

These reactions primarily occur within a titanium electrolyzer, which is categorized into two basic types: seawater electrolysis and brine electrolysis. The classification is based on the feedstock source, with seawater being used for seawater electrolysis systems and crystallized salt for brine systems.

The titanium electrode assembly is a critical component of the electrolytic cell. It is made up of a dimensionally stable anode (DSA) and a cathode, both made of titanium. The DSA is responsible for generating the chlorine gas, while the cathode produces hydrogen gas.

In summary, a Titanium Electrolytic Cell facilitates the electro-chlorination process by passing an electric current through a saltwater or brine solution, producing Sodium Hypochlorite and hydrogen gas as by-products. These reactions occur within the titanium electrolyzer, which is categorized based on the feedstock source, and the titanium electrode assembly plays a critical role in the process.

Chapt 3

Our Titanium Electrolyzer Cell offers numerous advantages that make it an excellent choice for various applications:

In summary, our Titanium Electrolytic Cell boasts excellent corrosion resistance, high stability, and long service life. With advanced technology and nano-coating, our cell ensures efficient and reliable performance while reducing salt and power consumption. Choose our Titanium Electrolytic Cell for your project and experience outstanding results.

Chapt 4

As a dedicated manufacturer of titanium electrolyzers for electrochlorination systems, we provide a comprehensive selection of sizes to cater to various needs in Seawater Electrochlorination and Brine Electrochlorination applications. Whether you seek a standard size or a tailored solution, our proficiency and manufacturing capabilities ensure unparalleled outcomes.

Ideal for coastal and offshore locations, this system is used in power plants, refineries, fertilizer plants, and desalination facilities. It controls biological activity in recirculating cooling systems that rely on seawater for cooling. The seawater electrochlorination system is cost-effective, especially in remote areas where other disinfection methods are challenging to implement.

|

Model |

Production (kgCl2/h) |

Amount of Seawater to be treated at 2ppm (m3 /h) |

Output Concentration (ppm) |

Seawater Flow Rate (m3/h) |

Electricity Consumption (kWh/kgCl2) |

|

HL-SW-5.0 |

5 |

2500 |

2000 |

2.5 |

4.5 |

|

HL-SW-10 |

10 |

5000 |

2000 |

5 |

4.5 |

|

HL-SW-20 |

20 |

10000 |

2000 |

10 |

4.5 |

|

HL-SW-40 |

40 |

20000 |

2000 |

20 |

4.5 |

|

HL-SW-60 |

60 |

30000 |

2000 |

30 |

4.5 |

|

HL-SW-80 |

80 |

40000 |

2000 |

40 |

4.5 |

|

HL-SW-100 |

100 |

50000 |

2000 |

50 |

4.5 |

|

HL-SW-140 |

140 |

70000 |

2000 |

70 |

4.5 |

|

HL-SW-180 |

180 |

90000 |

2000 |

90 |

4.5 |

|

HL-SW-200 |

200 |

100000 |

2000 |

100 |

4.5 |

|

HL-SW-400 |

400 |

200000 |

2000 |

200 |

4.5 |

|

HL-SW-800 |

800 |

400000 |

2000 |

400 |

4.5 |

|

HL-SW-1000 |

1000 |

500000 |

2000 |

500 |

4.5 |

Designed for artificial brine sources, these systems provide hypochlorite for disinfection. They are installed inland and produce significant amounts of sodium hypochlorite for storage, ensuring a constant disinfection capacity for applications where seawater isn’t accessible or for potable water chlorination.

|

Model |

Production (kgCl2/h) |

Amount of Water to be treated at 1ppm (m3 /h) |

Output Concentration (ppm) |

Brine Flow Rate (lit/h) |

Electricity Consumption (kWh/kgCl2) |

|

HL-BR-0.1 |

0.1 |

100 |

8000 |

12.5 |

4.8 |

|

HL-BR-0.5 |

0.5 |

500 |

8000 |

62.5 |

4.8 |

|

HL-BR-1.0 |

1 |

1000 |

8000 |

125 |

4.8 |

|

HL-BR-5.0 |

5 |

5000 |

8000 |

625 |

4.8 |

|

HL-BR-10 |

10 |

10000 |

8000 |

1250 |

4.8 |

|

HL-BR-20 |

20 |

20000 |

8000 |

2500 |

4.8 |

|

HL-BR-30 |

30 |

30000 |

8000 |

3750 |

4.8 |

|

HL-BR-40 |

40 |

40000 |

8000 |

5000 |

4.8 |

|

HL-BR-50 |

50 |

50000 |

8000 |

6250 |

4.8 |

Chapt 5

Titanium electrolyzers stand as a pivotal category within the realm of electrochemical devices, delineated into two distinct types: Concentric Tubular Electrolyzers (CTE) and Parallel Plate Electrolyzers (PPE). These advanced electrochemical systems leverage titanium’s exceptional properties to drive a spectrum of industrial processes and scientific investigations. Each type possesses a unique set of advantages, rendering them indispensable tools for researchers and engineers across diverse fields. In the following sections, we delve into the intricacies of these two titanium electrolyzer categories.

The Concentric Tubular Electrolyzer (CTE) stands as an advanced electrochemical marvel, boasting a distinctive design that features concentric titanium tubes.

In this configuration, the outer tube serves as the anode, while the inner tube takes on the role of the cathode, with an electrolyte solution flowing between them. CTEs are celebrated for their compactness, optimizing the surface area available for electrochemical reactions.

They find applications in vital sectors such as water treatment, metallurgy, and chemical synthesis, offering unparalleled precision and efficiency.

Parallel Plate Electrolyzer (PPE)

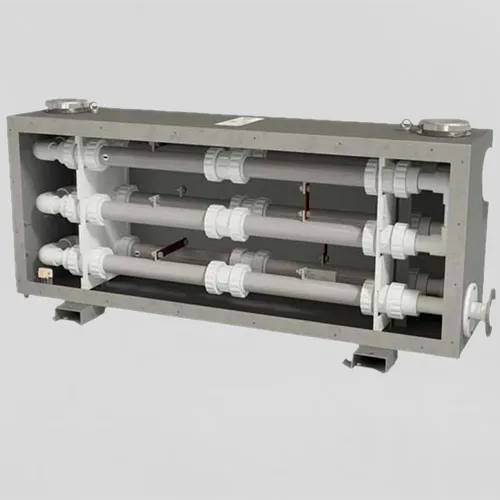

Parallel Plate Electrolyzer (PPE)The Parallel Plate Electrolyzer (PPE) emerges as a versatile electrochemical apparatus meticulously crafted for a multitude of industrial processes and scientific inquiries.

PPEs consist of flat titanium plates thoughtfully aligned in parallel within an electrolytic cell. This configuration ensures the uniform distribution of electric current, fostering efficient and finely controlled electrochemical reactions.

PPEs are distinguished by their remarkable efficiency and adaptability, making them well-suited for applications spanning electrolysis, electroplating, and the production of specialized chemicals. Researchers and engineers hold PPEs in high regard for their scalability, precision, and unwavering reliability.

Hele Titanium: Your Premier Titanium Electrolyzer Manufacturer

Hele Titanium: Your Premier Titanium Electrolyzer ManufacturerAt Hele Titanium, we take pride in our position as a leading titanium electrolyzer manufacturer, dedicated to the advancement of Salt & Seawater Electrochlorination technologies. With a commitment to excellence, we offer comprehensive, one-stop titanium electrolyzer services tailored to meet your diverse applications.

Our expertise and experience allow us to deliver the highest quality titanium electrolyzers for various industries, ensuring reliable and efficient electrochemical processes. Whether you require electrolyzers for saltwater or seawater applications, Hele Titanium is your trusted partner in achieving superior results.

Experience the difference with Hele Titanium and elevate your electrochemical innovations to new heights.

Chapter 6

Titanium Electrolytic Cells have a wide range of applications across various sectors, making them valuable assets for many industries. These electrolyzers are integral to processes such as electro-chlorination, water disinfection, and sodium hypochlorite generation.

Their adaptability makes them useful in industries such as water treatment, chemical production, and many more. By utilizing these powerful electrolytic cells, you can enhance efficiency and performance in a wide range of settings.

Explore the versatile world of Titanium Electrolyzers and discover how they can be implemented to meet your specific needs. Whether you’re looking to improve production processes, increase efficiency, or enhance water quality, Titanium Electrolyzers offer an effective and reliable solution.

In industrial sectors such as cement, steel, and power generation, cooling water is vital. However, using seawater for cooling often leads to fouling issues caused by algae and pathogens, reducing system efficiency.

Titanium electrolyzers, designed for seawater electro-chlorination, provide a comprehensive solution. They continuously produce sodium hypochlorite, a potent disinfectant introduced in microdoses. This disinfectant, coupled with efficient filters, effectively removes slime, sand, and aquatic life. Additionally, occasional shock doses of chlorine prevent microorganism regrowth.

In essence, titanium electrolyzers play a pivotal role in maintaining and improving cooling water quality, ensuring optimal system performance across various industries.

Marine fleets depend on a consistent water supply, often stored in tanks vulnerable to algae and microorganism growth, which can compromise water quality. To combat this, Hele Titanium offers top-quality titanium electrolytic cells for seawater electro-chlorination systems, providing on-demand Sodium Hypochlorite for efficient on-site water disinfection.

Our electrolytic cells are reliable, efficient, and easy to install, making them the ideal choice for marine fleets. They effectively disinfect water tanks, ensuring stored water remains safe and potable.

Sodium Hypochlorite, generated by our cells, acts as a potent disinfectant, eradicating harmful microorganisms and preventing algae and contaminants. Enhance your marine and cruise water disinfection with Hele Titanium’s advanced technology.

In rural areas, access to clean and safe drinking water is a fundamental necessity. However, water sources in such regions are often susceptible to contamination, leading to waterborne diseases and health concerns.

Titanium electrolyzers, specially tailored for rural water treatment, offer an effective solution. These systems continuously produce sodium hypochlorite, a powerful disinfectant, in precise microdoses. When introduced into the water supply, this disinfectant effectively neutralizes harmful microorganisms, ensuring the water remains safe for consumption.

Moreover, the integration of efficient filtration systems further enhances water quality by removing impurities and sediment. Occasional shock doses of chlorine provided by the titanium electrolyzers serve as an additional layer of protection, preventing the growth of microorganisms.

In densely populated urban areas, ensuring the availability of safe and clean drinking water is paramount. However, challenges such as water pollution and contamination persist. Titanium electrolyzers, specifically designed for urban water treatment, offer a comprehensive solution.

These advanced systems continuously produce sodium hypochlorite, a potent disinfectant, in precise microdoses. When introduced into the water supply, this disinfectant effectively neutralizes harmful microorganisms, pathogens, and contaminants, guaranteeing the safety of the urban water distribution network.

Moreover, the incorporation of efficient filtration systems enhances water quality by removing impurities, sediment, and suspended particles. Titanium electrolyzers are also equipped to respond to fluctuations in water demand, ensuring a consistent supply of clean water to urban residents.

Wastewater treatment is a critical process to safeguard the environment and public health. Titanium electrolyzers are at the forefront of this transformation. Specifically engineered for wastewater treatment, these advanced systems generate sodium hypochlorite, a powerful disinfectant, in precise microdoses. When introduced into the wastewater, this disinfectant effectively eliminates harmful microorganisms and contaminants.

Furthermore, titanium electrolyzers enhance the process by effectively oxidizing and breaking down organic pollutants and reducing the overall chemical demand in wastewater treatment plants. Their efficiency, reliability, and adaptability make them indispensable tools for upgrading wastewater treatment infrastructure and achieving cleaner and more sustainable water discharges.

Safety is paramount in the food and beverage industry, and titanium electrolyzers are making a significant impact. Designed for food and beverage applications, these systems produce sodium hypochlorite, a potent disinfectant, in precise microdoses.

This disinfectant is a versatile tool used for surface disinfection, equipment sterilization, and water treatment in various production stages. It effectively neutralizes harmful microorganisms, ensuring a safer and more hygienic food and beverage supply chain.

Furthermore, sodium hypochlorite extends product shelf life, reduces waste, and enhances overall quality. With their efficiency, reliability, and ease of integration, titanium electrolyzers play a vital role in upholding stringent food and beverage safety standards.

For pristine and safe pool water, titanium electrolyzers offer an efficient solution. Designed for pool water applications, these systems generate sodium hypochlorite, a potent disinfectant, in precise microdoses. This disinfectant effectively eliminates harmful microorganisms, ensuring a hygienic swimming environment.

By reducing the need for traditional chlorine chemicals, sodium hypochlorite from titanium electrolyzers minimizes environmental impact. These systems provide a reliable source of chlorine, ensuring consistently balanced and safe pool water.

In essence, titanium electrolyzers are revolutionizing pool water treatment, offering an eco-friendly and efficient solution for clean and inviting swimming pools.

Chapt 8

When custom titanium electrolytic cells from us, it’s essential to provide your specific needs and requirements. This enables our team to craft a customized electrolyzer that aligns perfectly with your application. To ensure an ideal match, please take into account the following crucial parameters:

By carefully considering these parameters, you can ensure that your electrolytic cell is designed to meet your unique requirements and deliver optimal performance. Our team of experts can assist you in making these decisions and creating a customized titanium electrolyzer that meets your specific needs. With our tailored solutions, you can be confident that you are getting the exact product you need for your project.

Chapt 8

When it comes to purchasing a titanium electrolytic cell or titanium electrolyzer, the process can be overwhelming due to the multitude of options available. However, with the right research and guidance, it is possible to find a reputable supplier that can meet your specific needs.

Hele Titanium is a trusted supplier of titanium electrolytic cells and electrolyzers, with over ten years of experience in the industry. Our products are available in a variety of materials, finishes, and specifications, making them suitable for projects of all sizes and requirements. Whether you need a single cell for a DIY project or a complete Electro Chlorinator system for industrial use, we have the expertise to assist you. Contact us today to learn more about our titanium electrolyzers and how we can help you find the perfect solution for your needs.

No matter the specific titanium MMO electrolyzer requirements you have, our vast expertise enables us to produce it for you. Notably, as we create our own raw materials, we have the advantage of delivering superior quality control and more competitive pricing compared to our worldwide competitors.