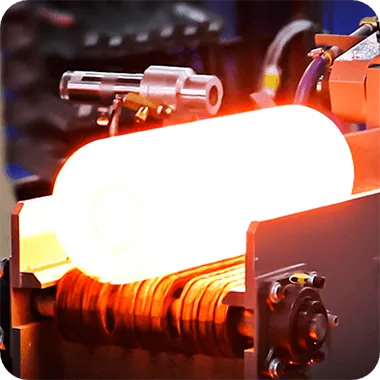

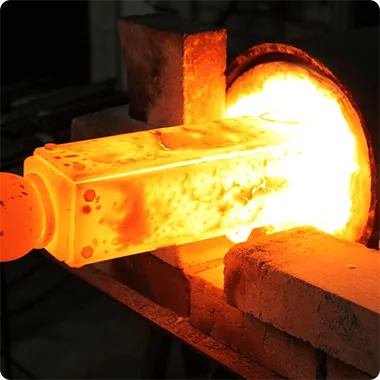

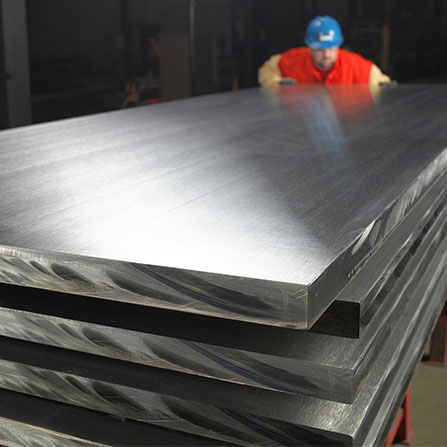

At Hele Titanium, we have implemented a comprehensive quality control system that spans every stage of production for our milled and machined titanium products. Our primary objective is to ensure that we deliver only the highest quality titanium to our customers.

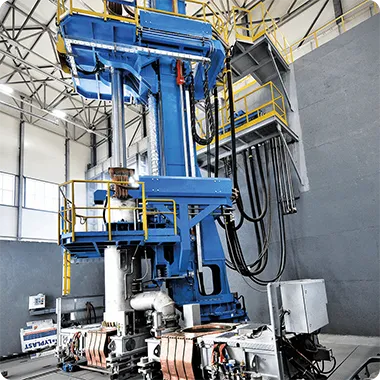

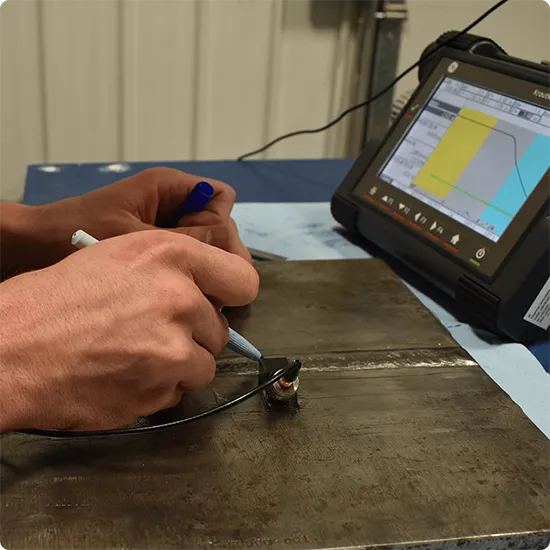

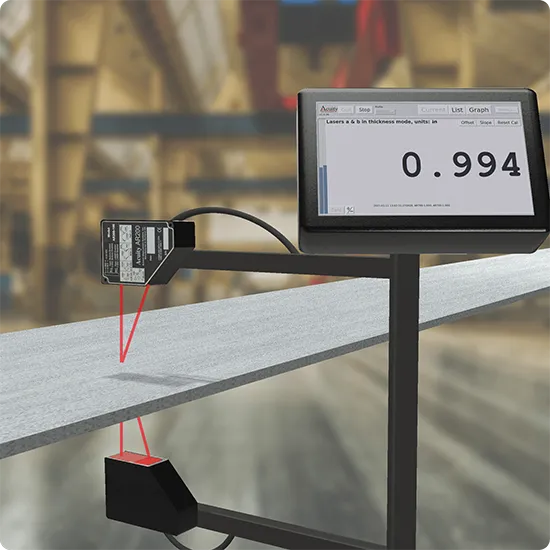

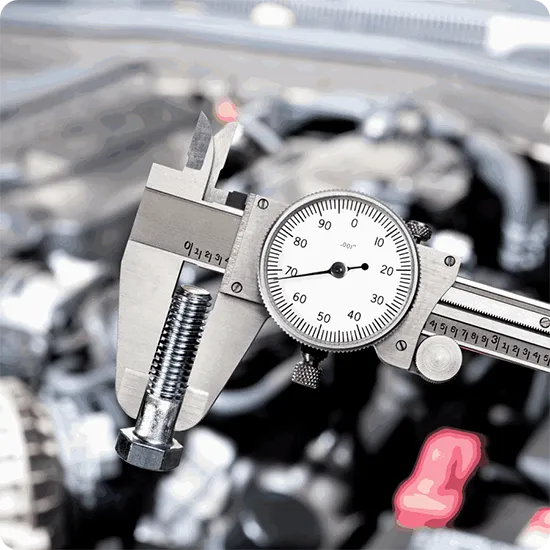

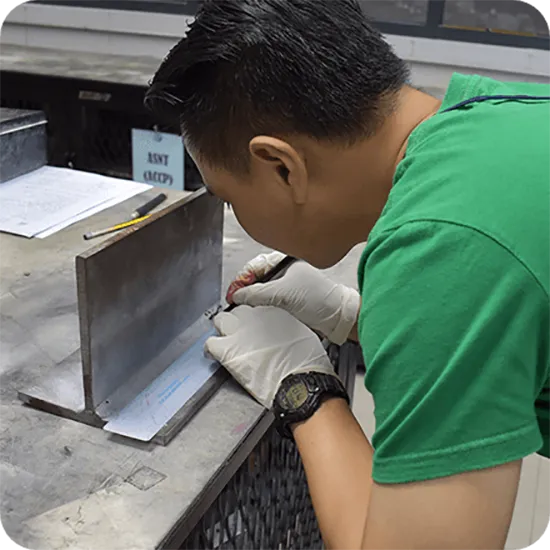

Our quality standards include inspecting the chemicals used at every stage of production, verifying the functionality of our equipment, and utilizing ultrasonic equipment to test the hardness and dimensional accuracy of our products.

Furthermore, our titanium products are ISO certified, and we uphold these standards throughout the entire production process to guarantee the consistency and reliability of our products. Please contact us for more information about our quality assurance processes.