In Summary

Navigating the multitude of titanium fittings might appear daunting, particularly for those new to the field. Nevertheless, armed with the right knowledge about titanium fittings, selecting the ideal supplier becomes a more straightforward endeavor.

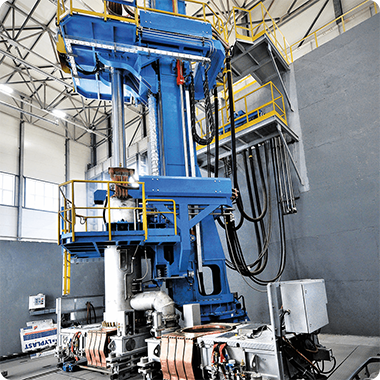

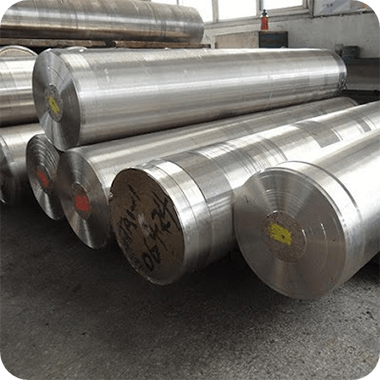

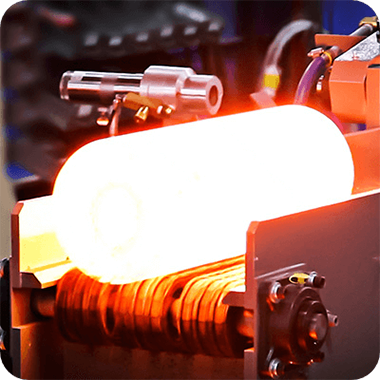

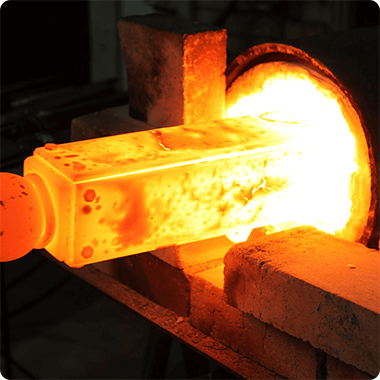

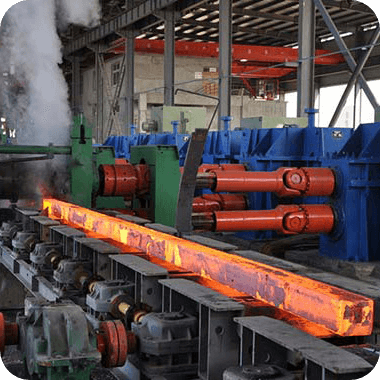

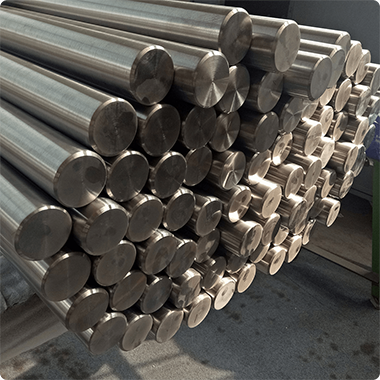

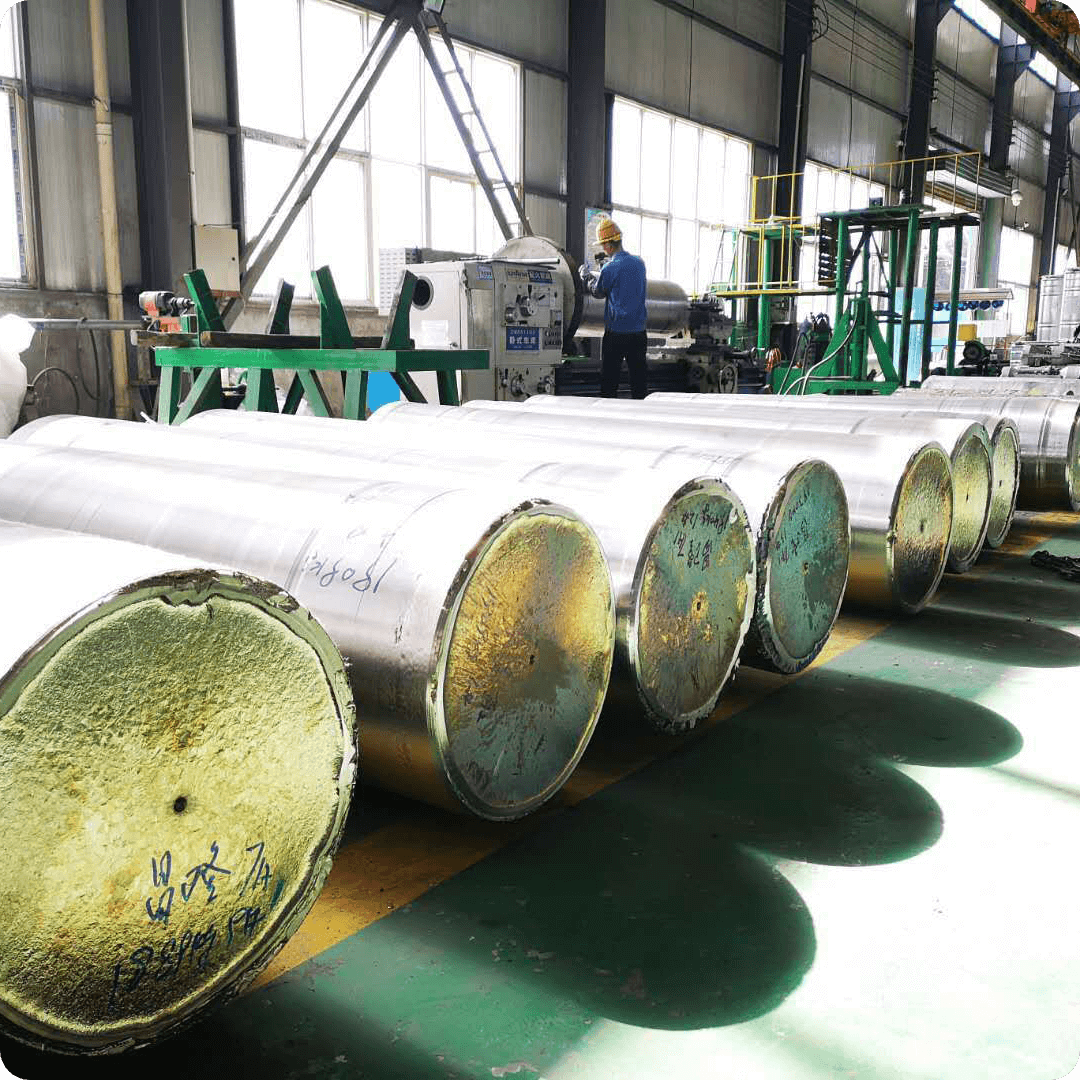

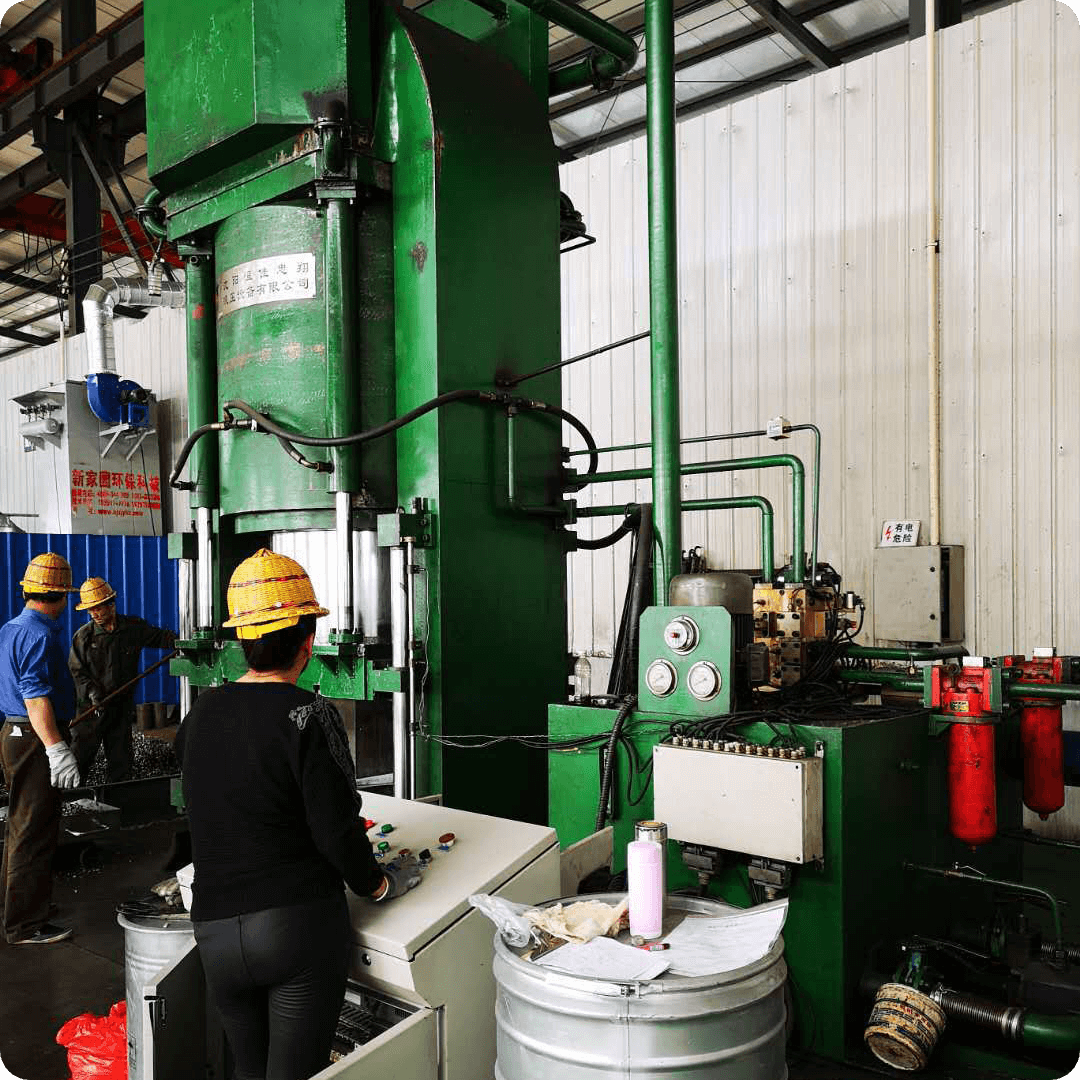

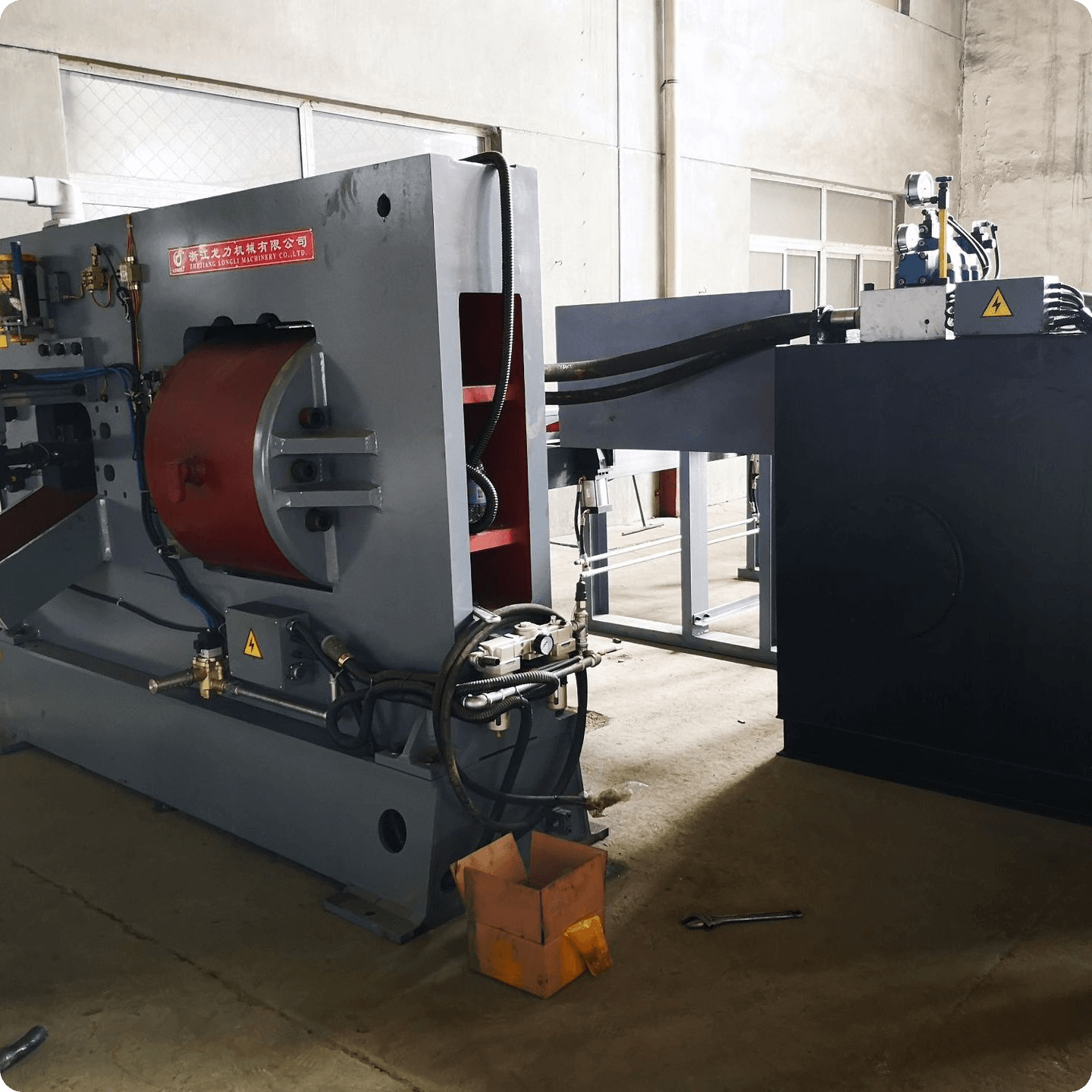

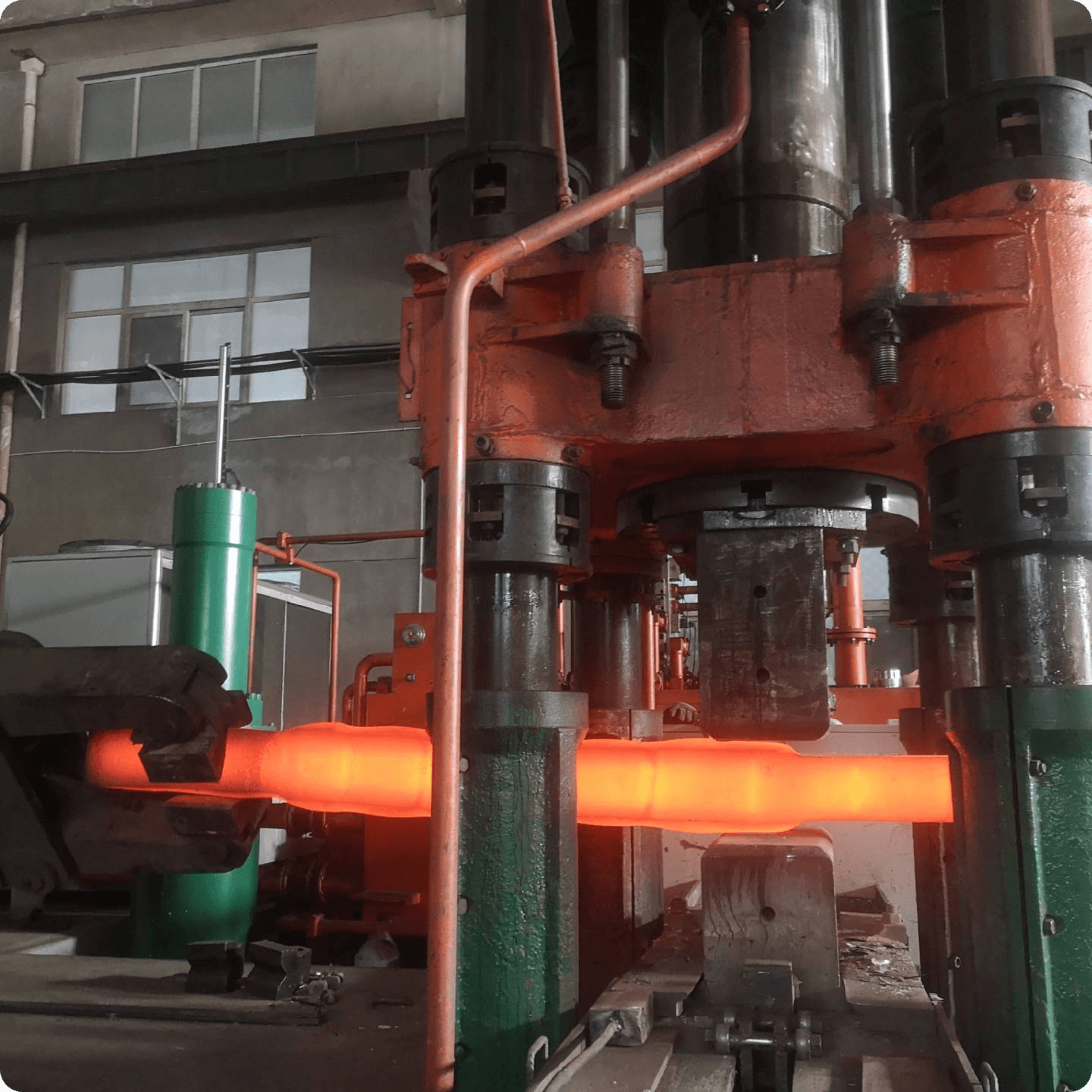

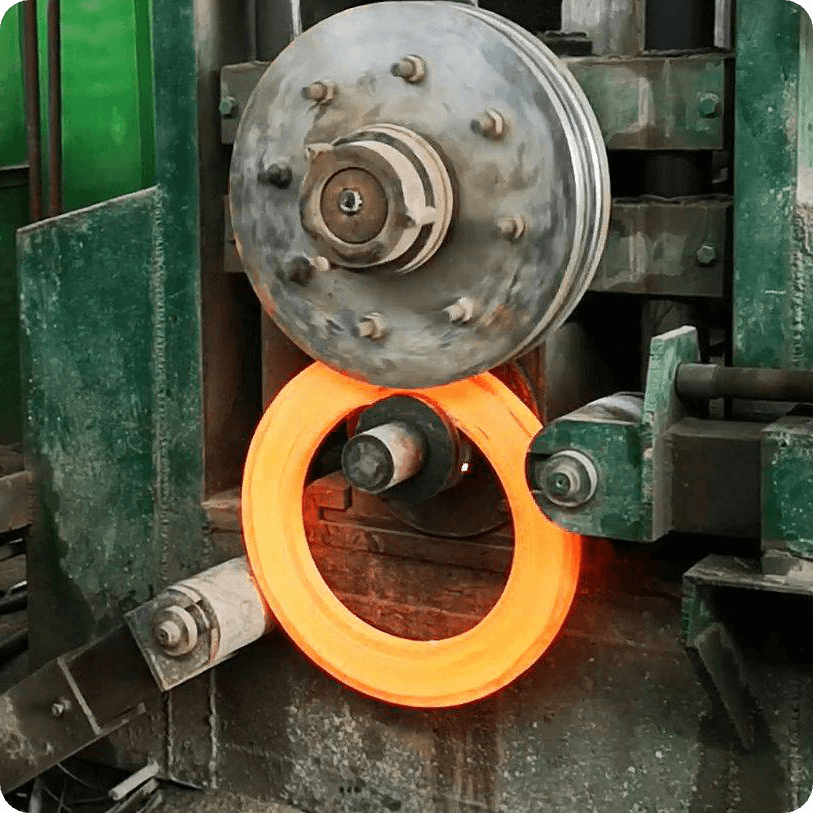

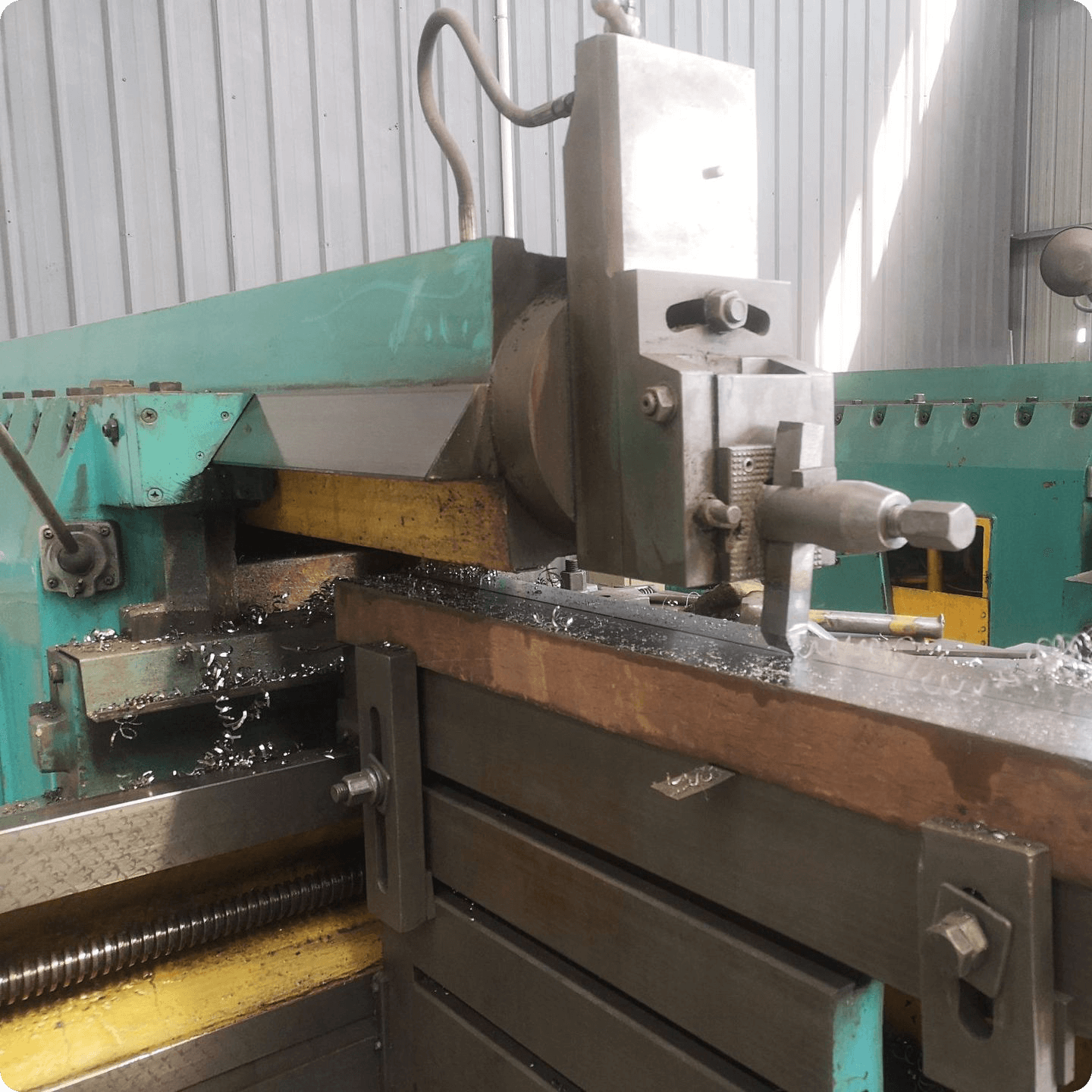

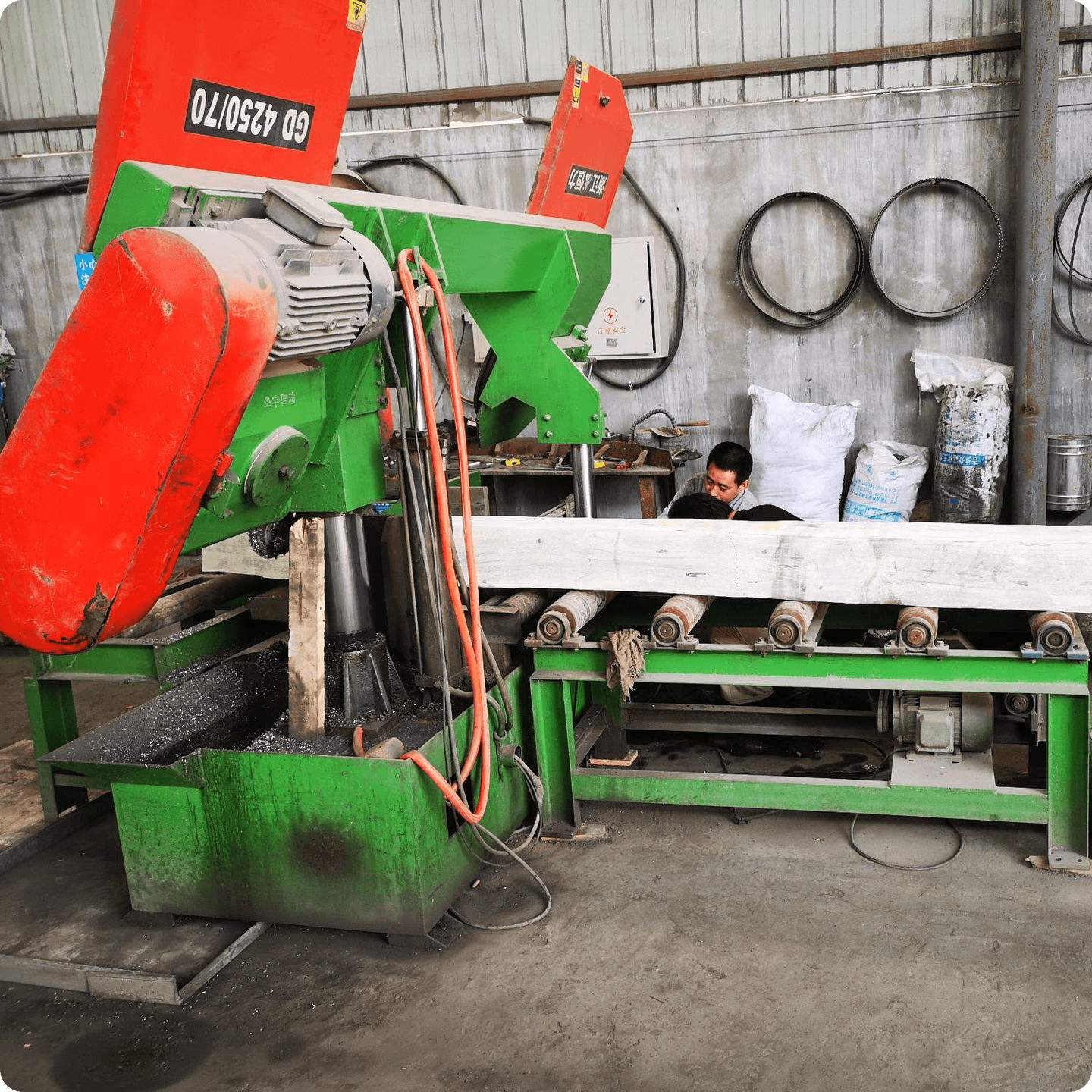

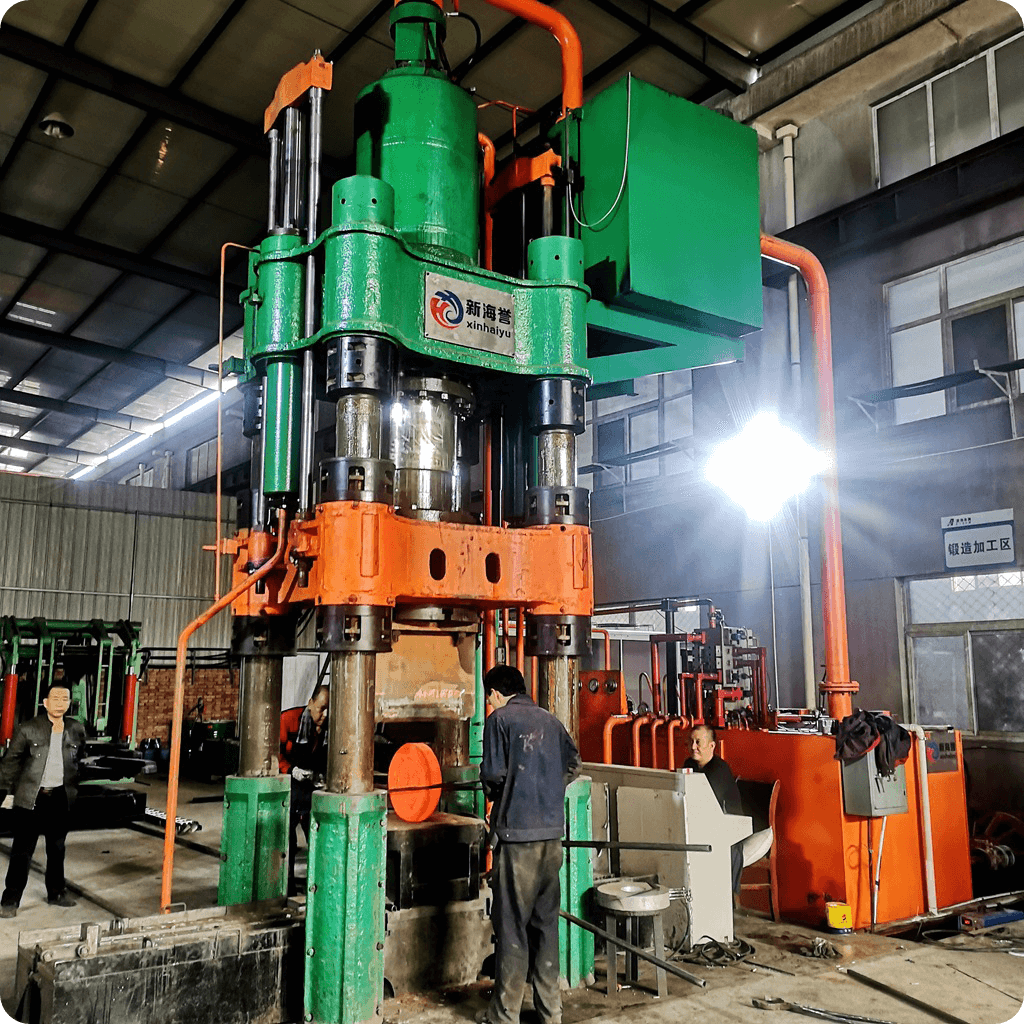

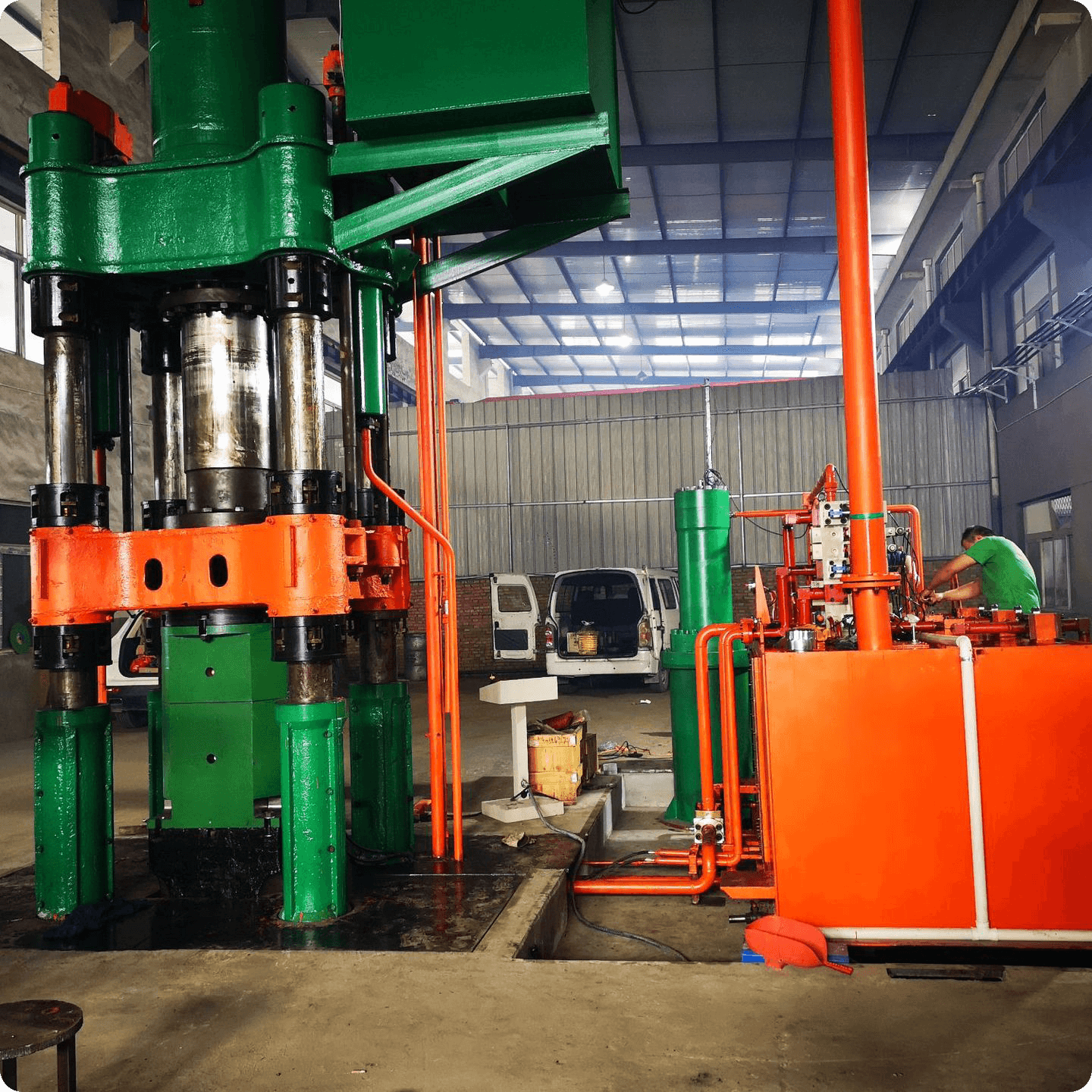

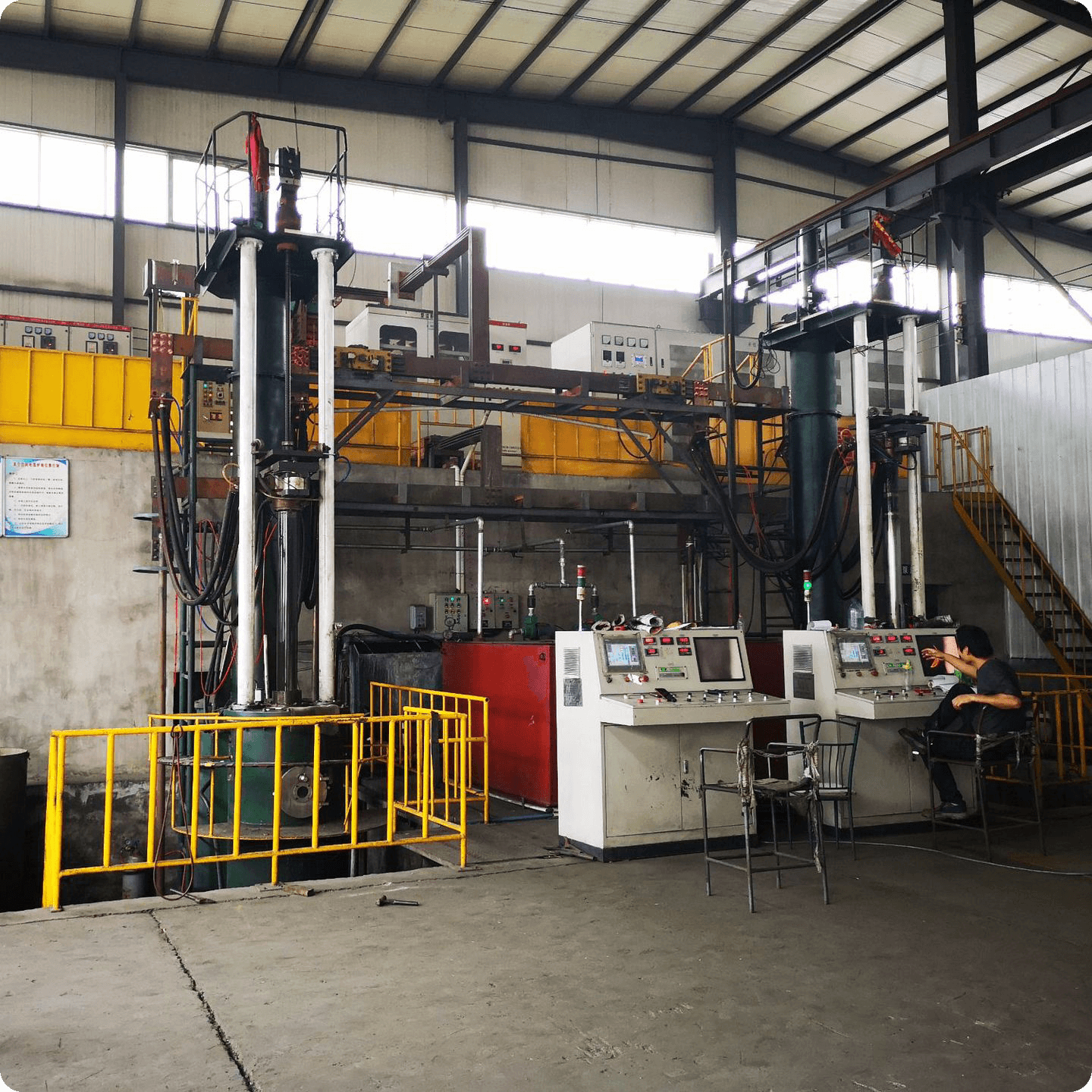

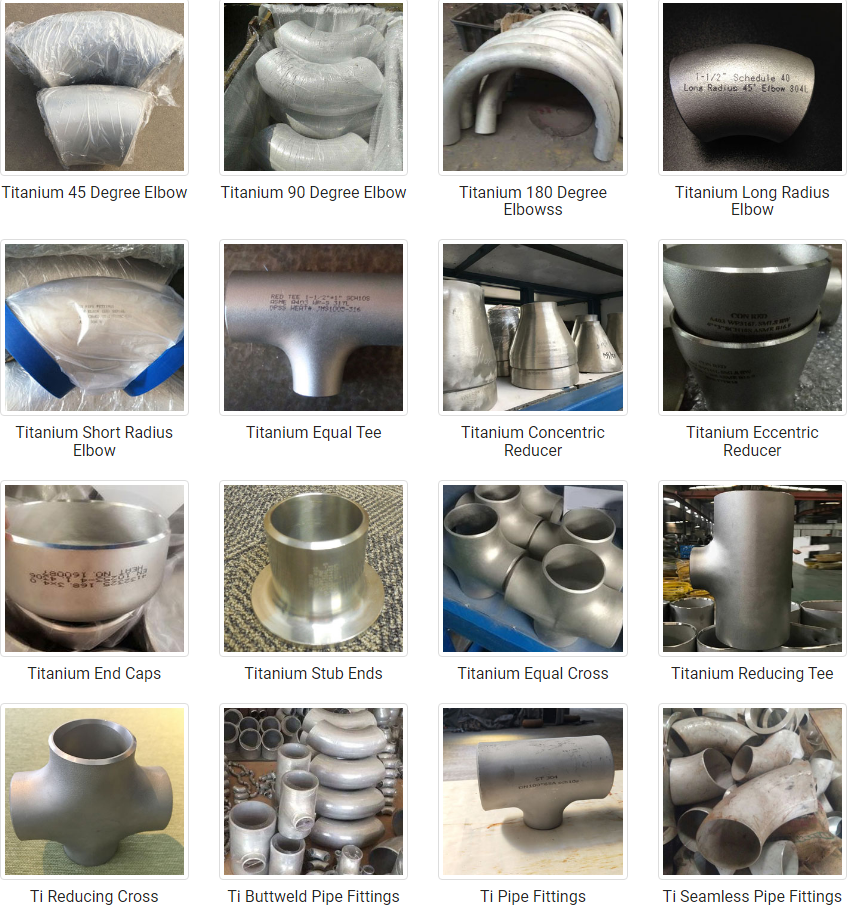

With over a decade of experience in the titanium fitting industry, Hele Titanium emerges as a premier supplier. Our extensive range encompasses elbows, tees, caps, reducers, flanges, and more. Beyond titanium forged pipe fittings, we provide comprehensive solutions, including titanium buttweld elbows, T-fittings, flanges, and gaskets for assembly, along with individual components.

Irrespective of the scale of your project, our team stands ready to support you at every stage. At Hele Titanium, our unwavering commitment is to deliver exceptional service and products tailored precisely to your requirements. Whether your project is grand or modest, we are fully equipped to meet your needs with precision and unwavering dedication.

Titanium fittings come in various types, each designed to serve specific purposes in fluid and gas systems. Here are some common types along with their standard size specifications and applications:

Titanium fittings come in various types, each designed to serve specific purposes in fluid and gas systems. Here are some common types along with their standard size specifications and applications: Titanium fittings find versatile applications across a wide range of industries due to their exceptional qualities. Some common applications include:

Titanium fittings find versatile applications across a wide range of industries due to their exceptional qualities. Some common applications include: When purchasing titanium fittings, several key considerations ensure you make an informed and suitable choice for your application:

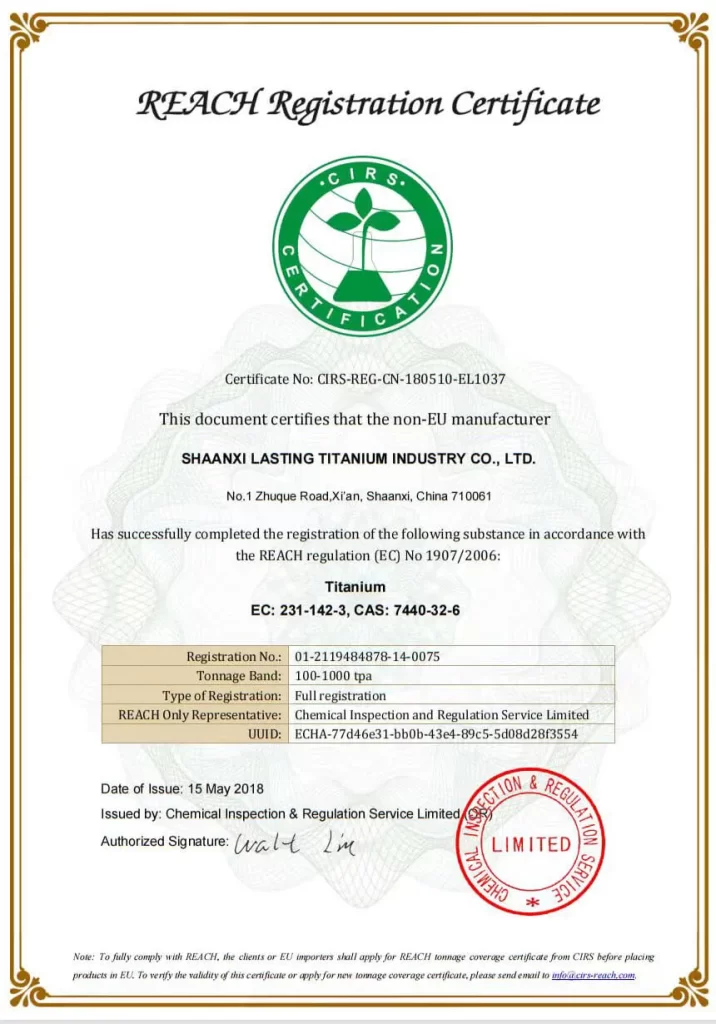

When purchasing titanium fittings, several key considerations ensure you make an informed and suitable choice for your application: When seeking a dependable titanium fitting supplier, follow these steps to ensure you make the right choice:

When seeking a dependable titanium fitting supplier, follow these steps to ensure you make the right choice: