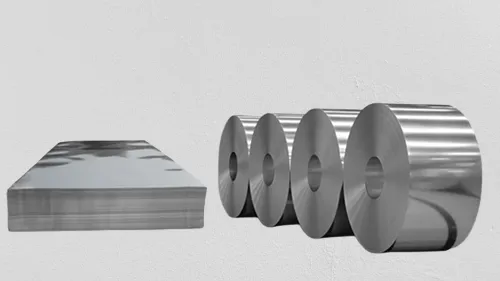

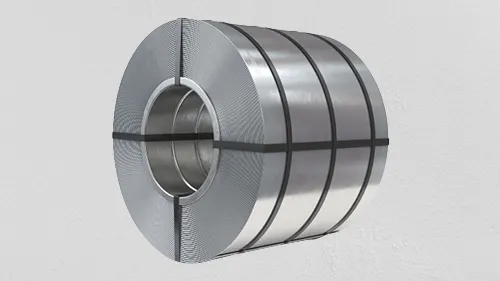

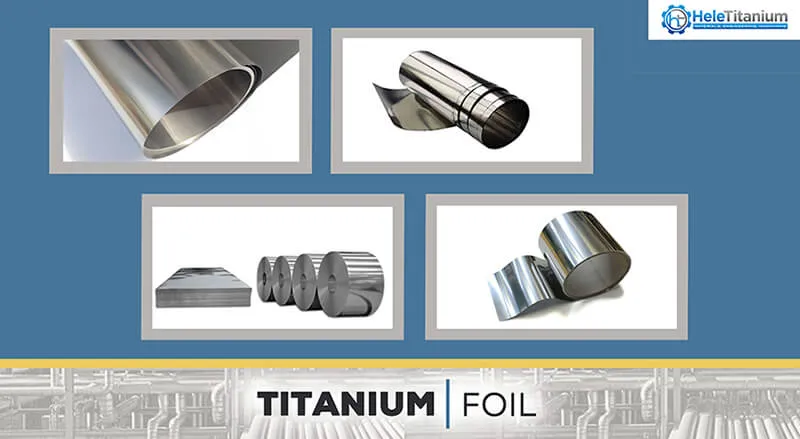

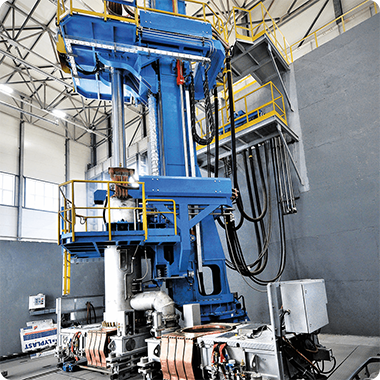

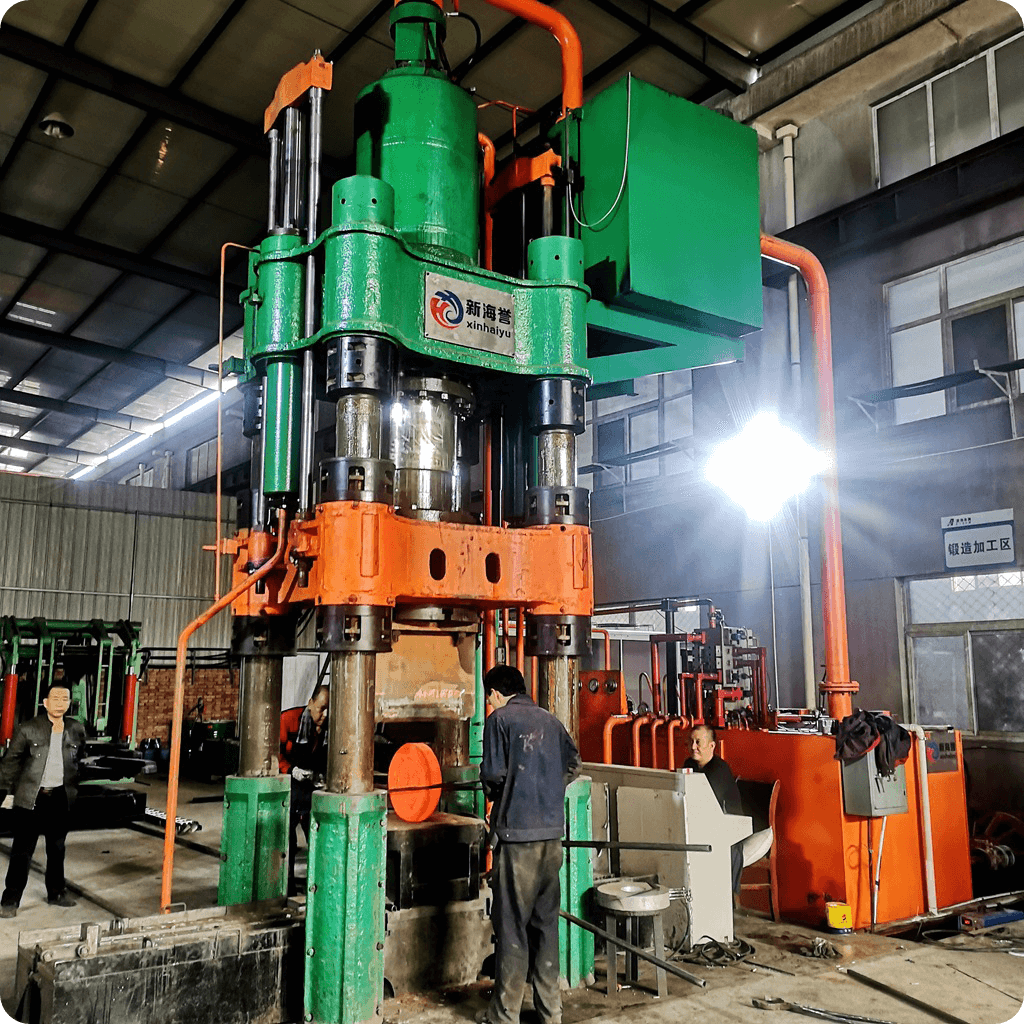

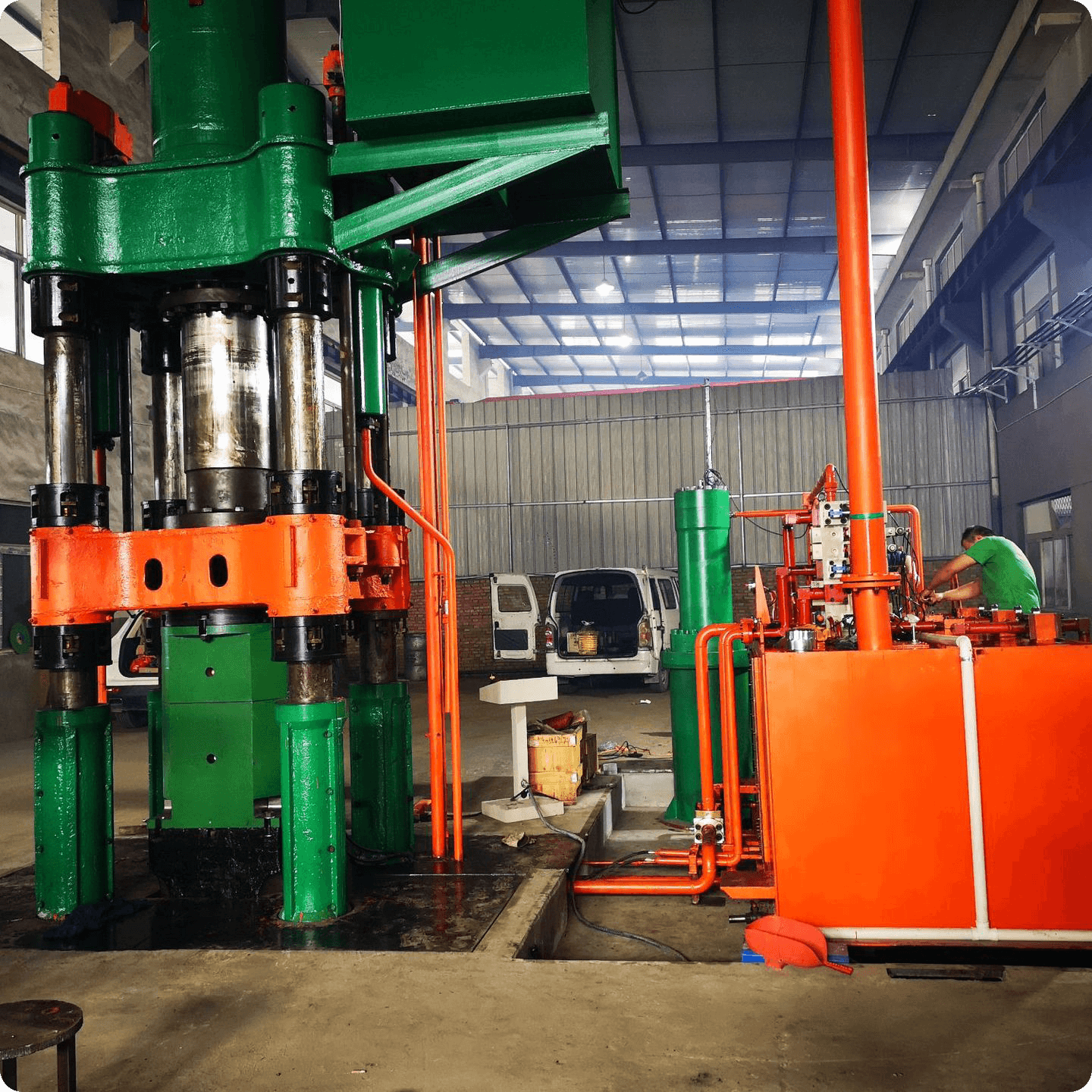

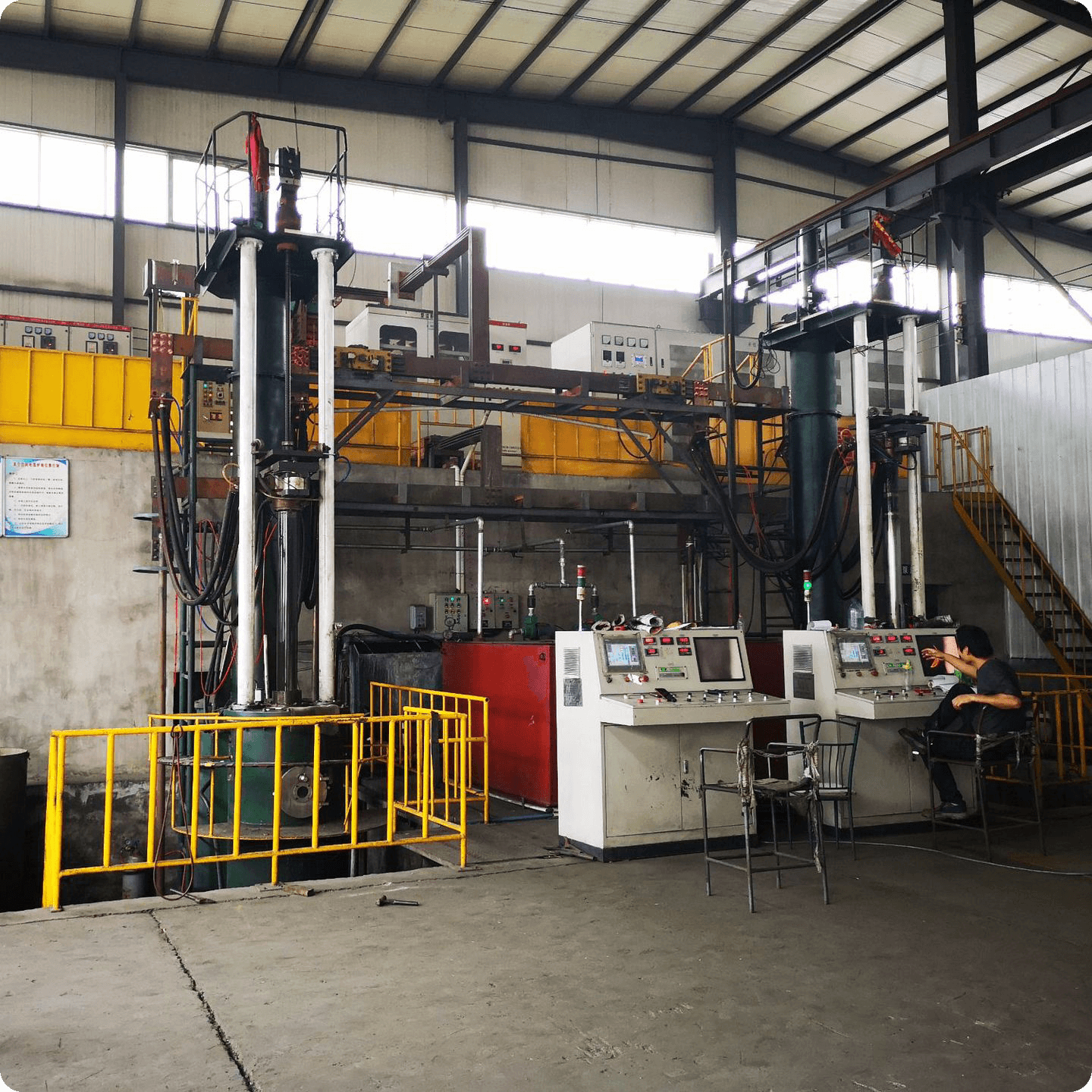

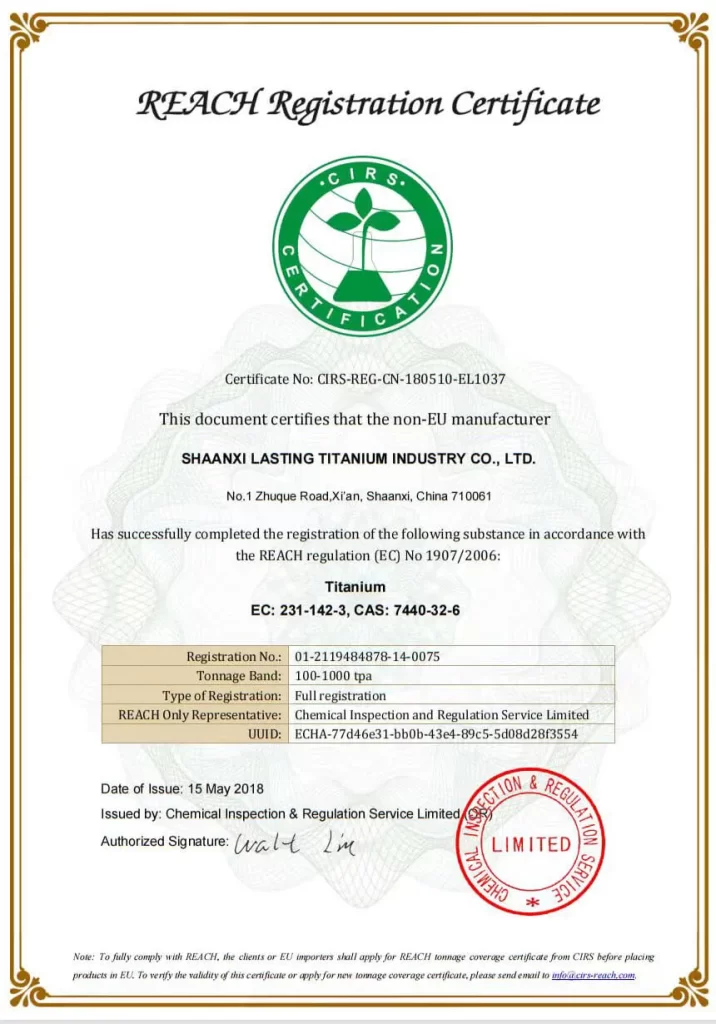

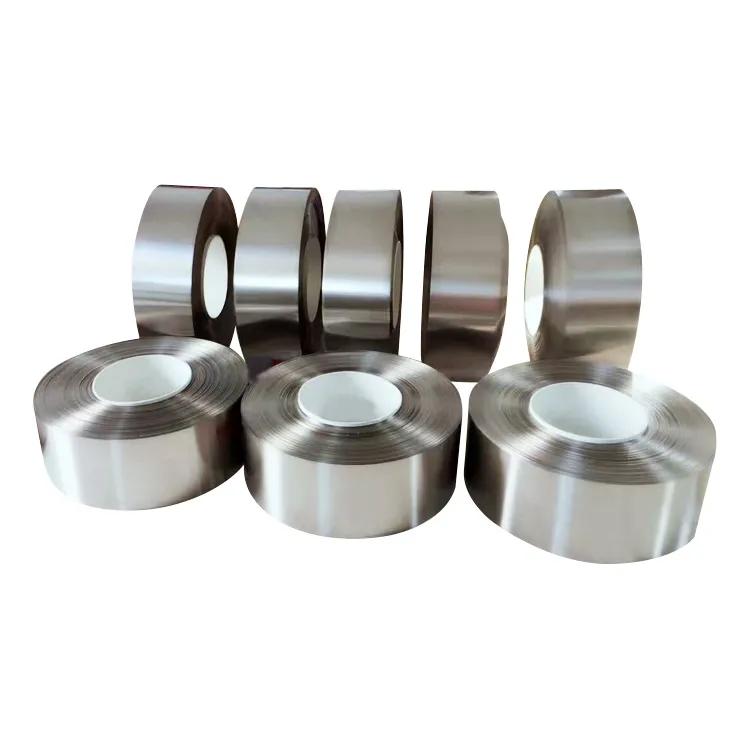

Hele Titanium is your trusted partner for precision-engineered titanium foil manufacturing. With over a decade of industry excellence, we are dedicated to crafting titanium foil perfectly aligned with your unique project requirements. When you choose Hele, you’re opting for unparalleled quality, delivered promptly every time.

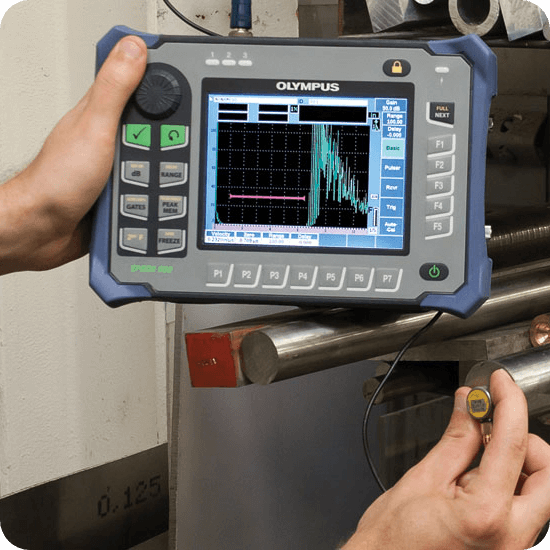

When searching for a trustworthy titanium foil supplier, consider the following steps to ensure you make the right choice:

When searching for a trustworthy titanium foil supplier, consider the following steps to ensure you make the right choice: