In Summary

Amidst the array of titanium wire options, the journey of selection may appear daunting, especially for new buyers. However, by investing in research and seeking guidance on titanium wire and welding, you can streamline your choices and discover a dependable supplier that aligns with your needs.

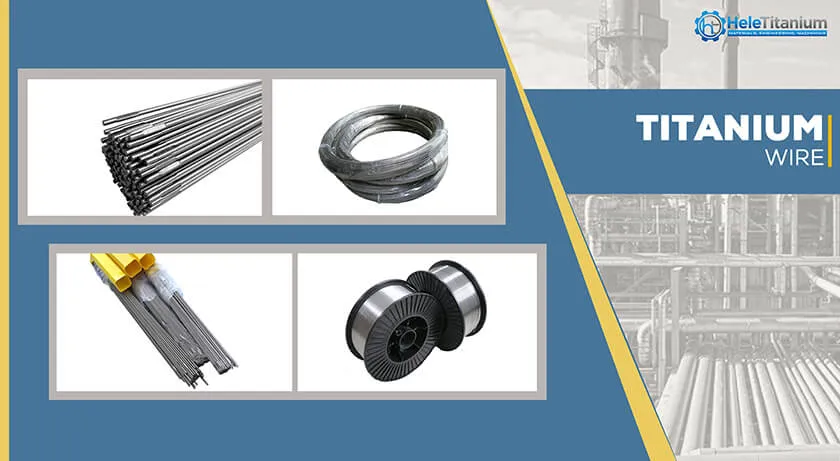

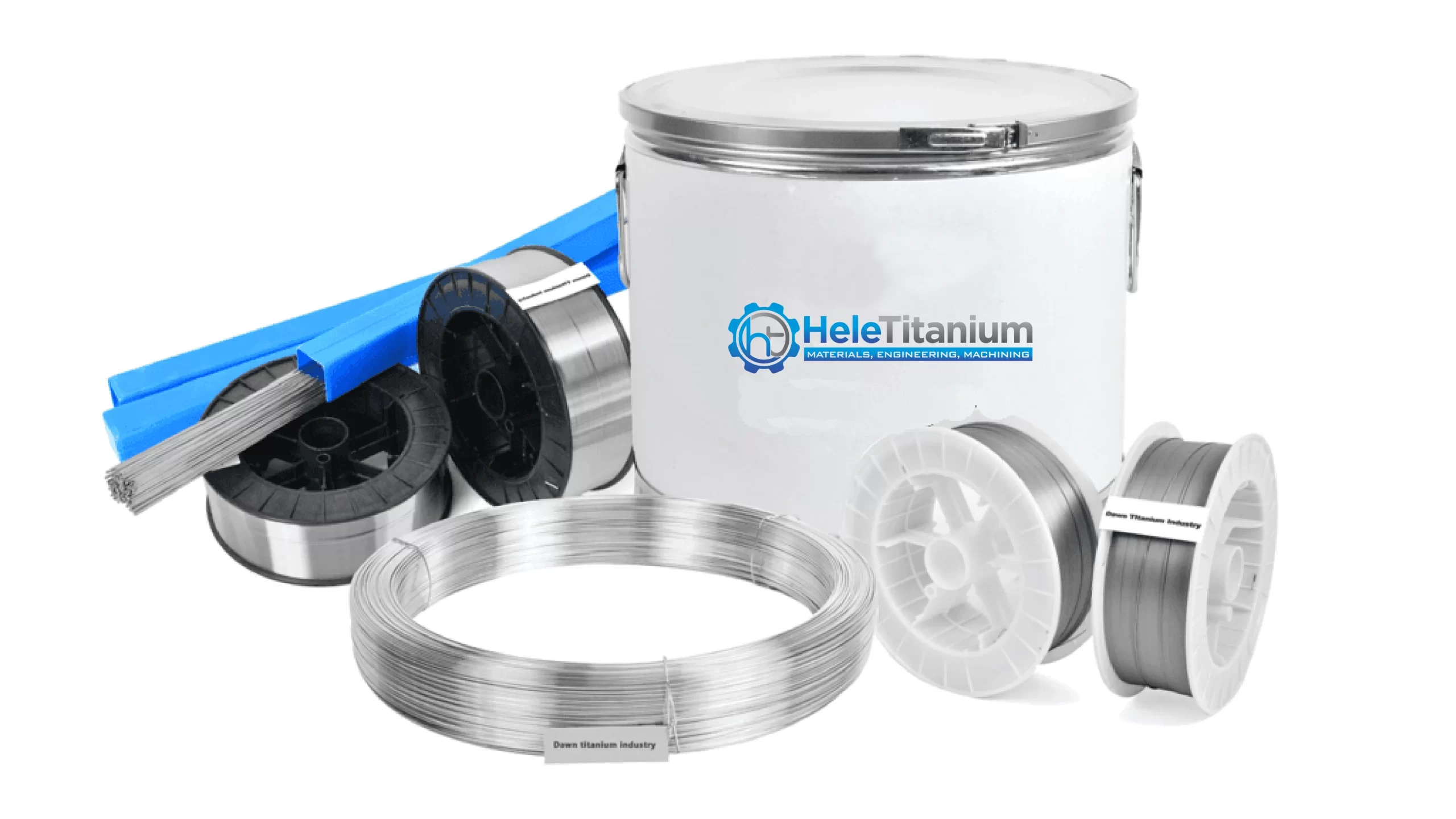

Enter Hele Titanium, a trusted supplier boasting over a decade of industry expertise. We offer customized materials, finishes, and specifications tailored to a wide range of projects. Whether your endeavors are small or large, our experienced team is fully equipped to assist you. We even go the extra mile by crafting custom samples to meet your specific requirements. No project is too extensive for us to handle!

For all your titanium requirements, don’t hesitate to reach out to us. We are unwavering in our commitment to delivering top-quality products and providing exceptional customer service, ensuring the resounding success of your projects.

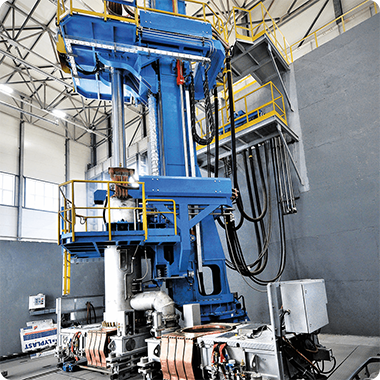

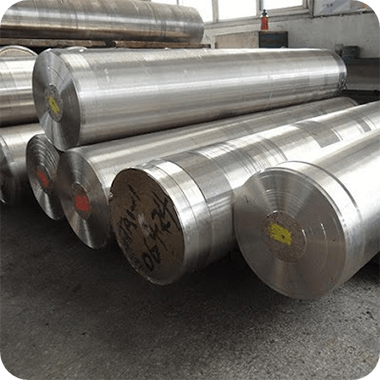

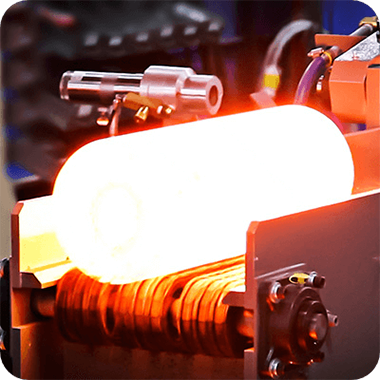

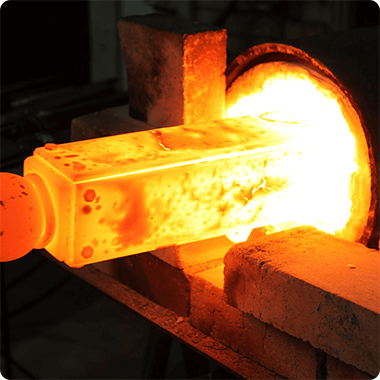

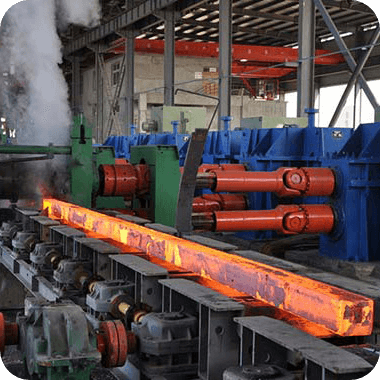

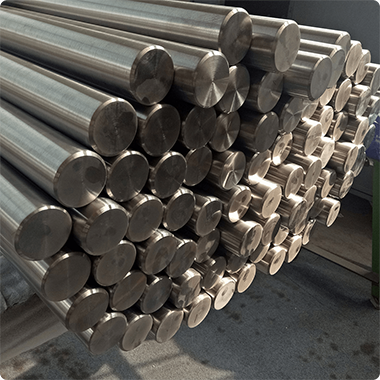

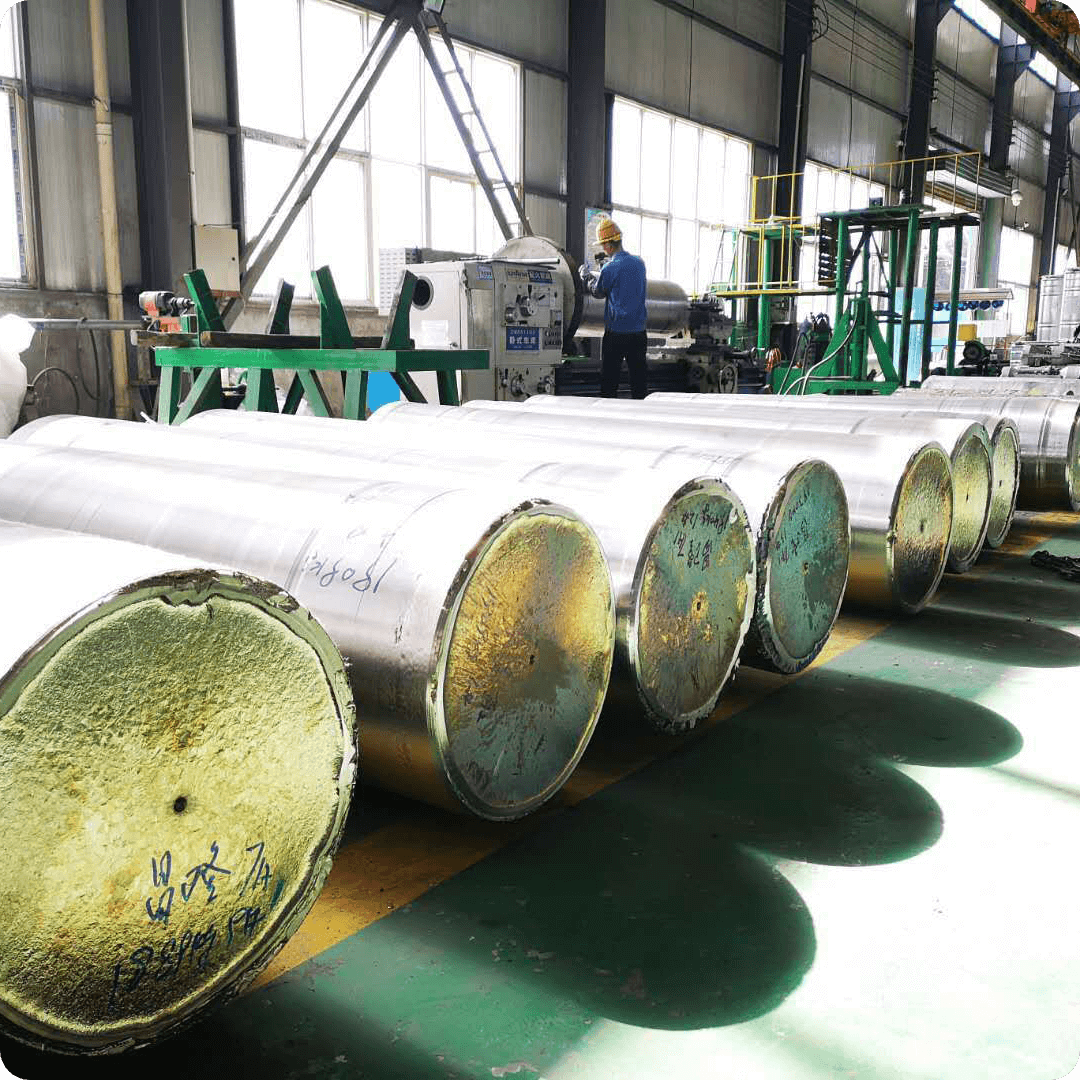

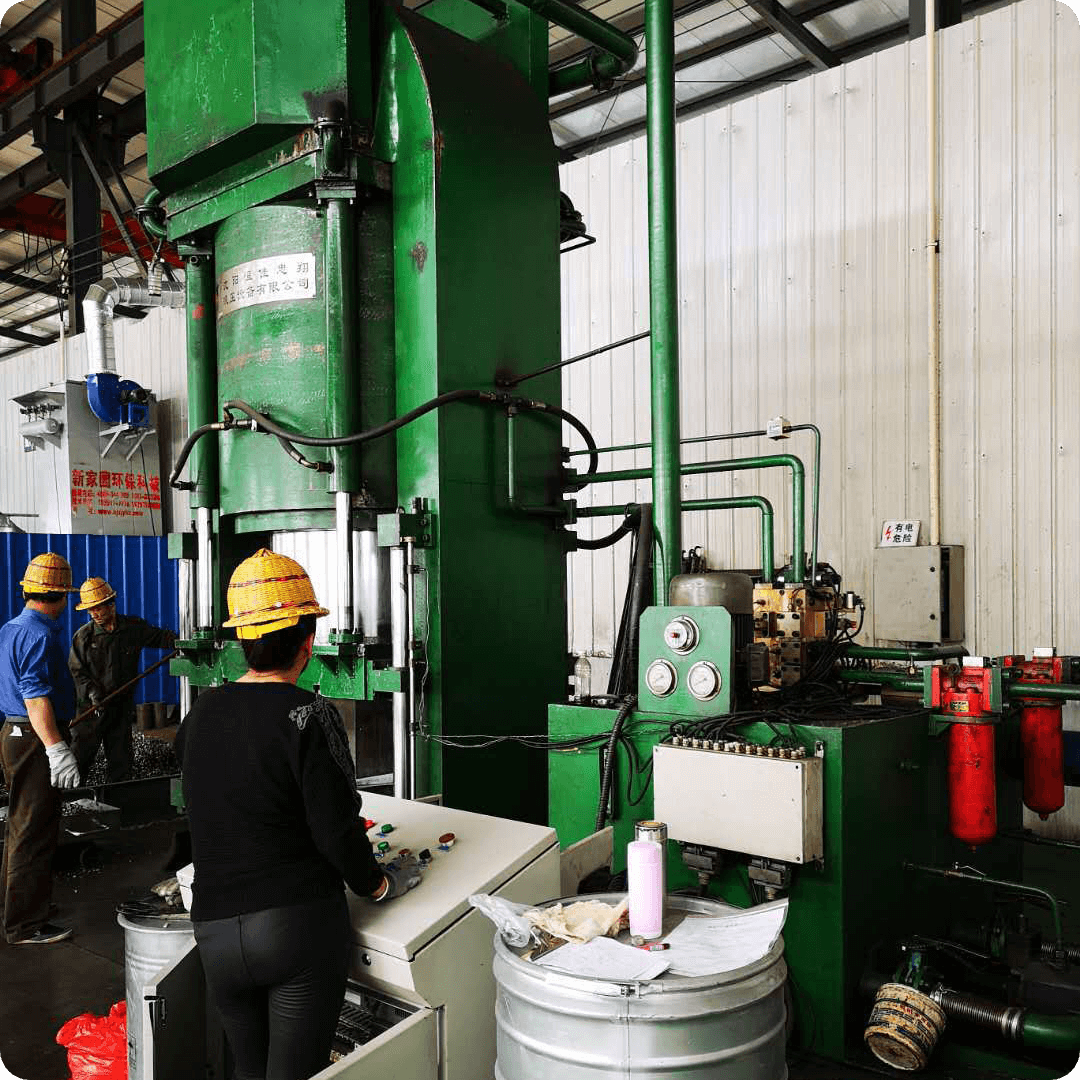

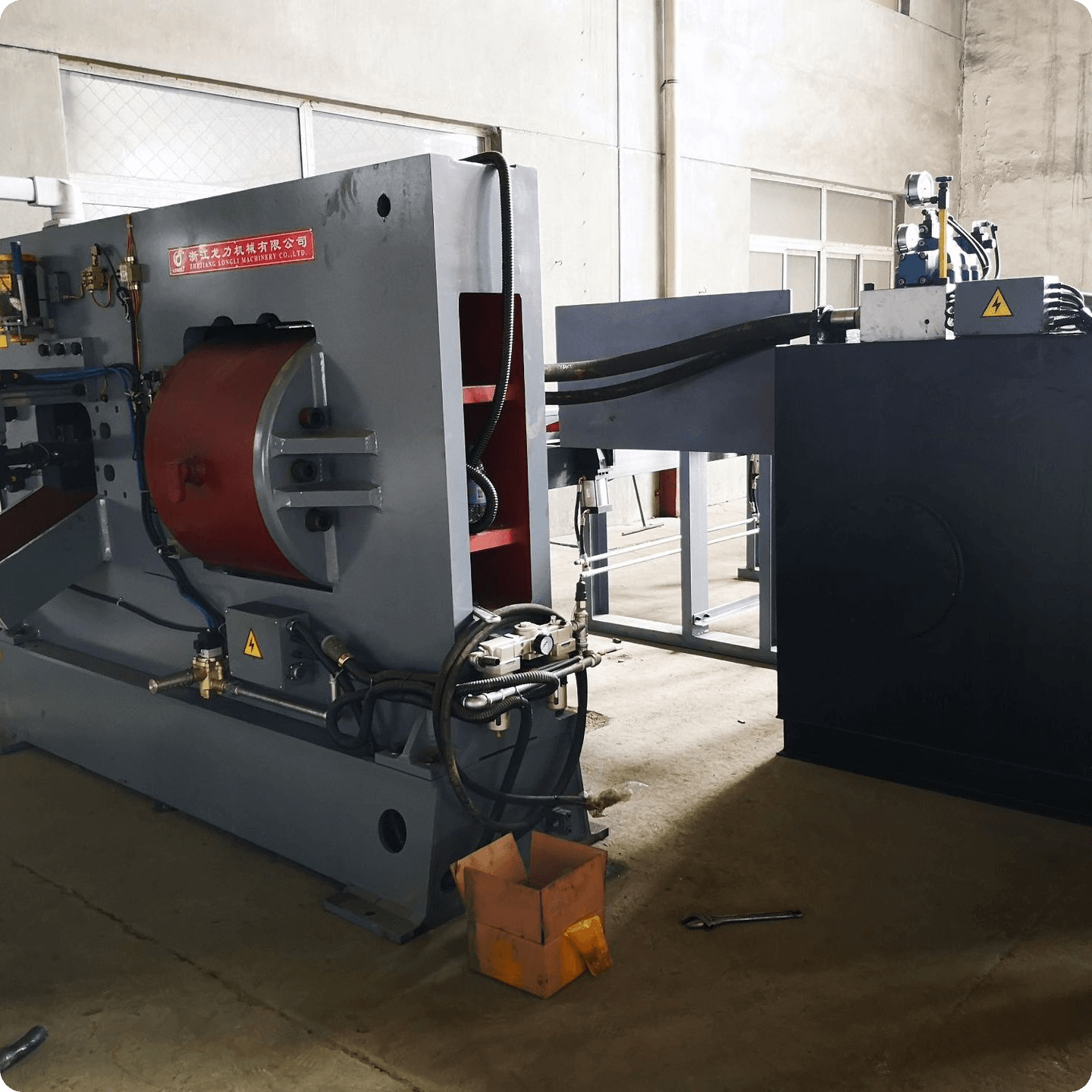

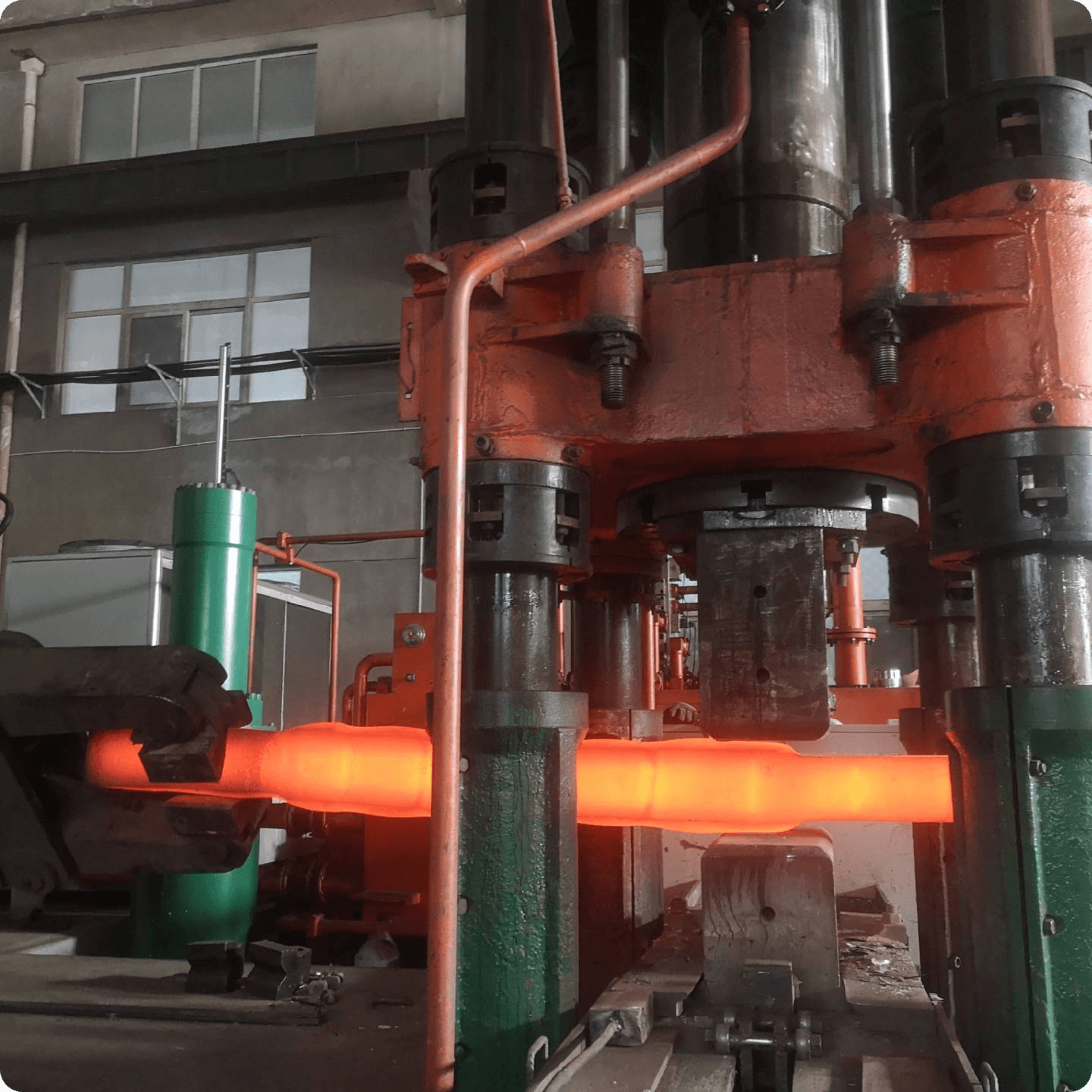

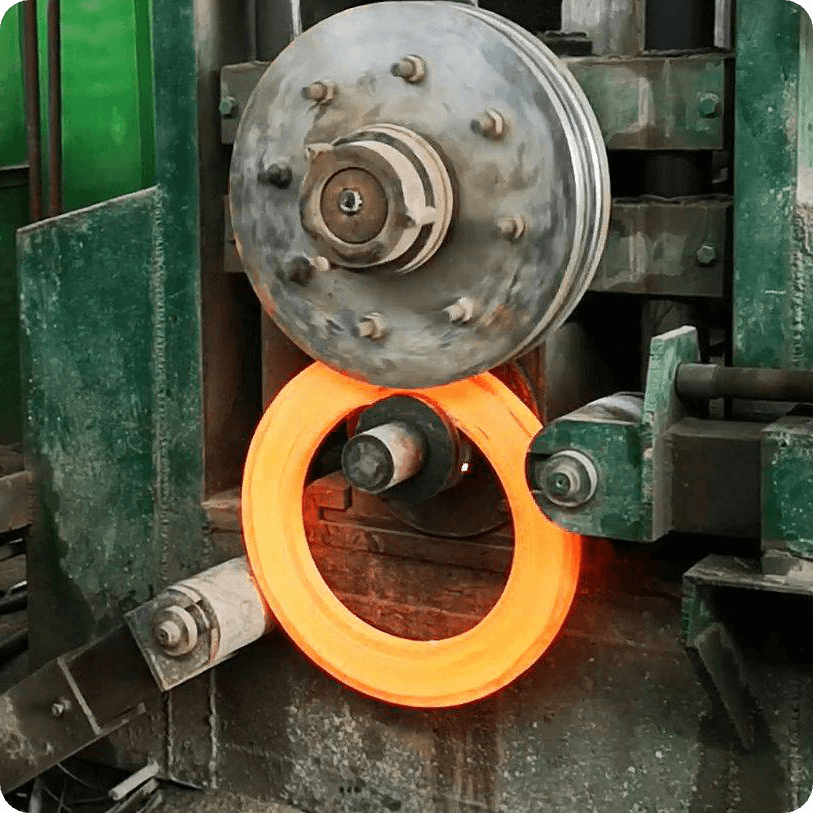

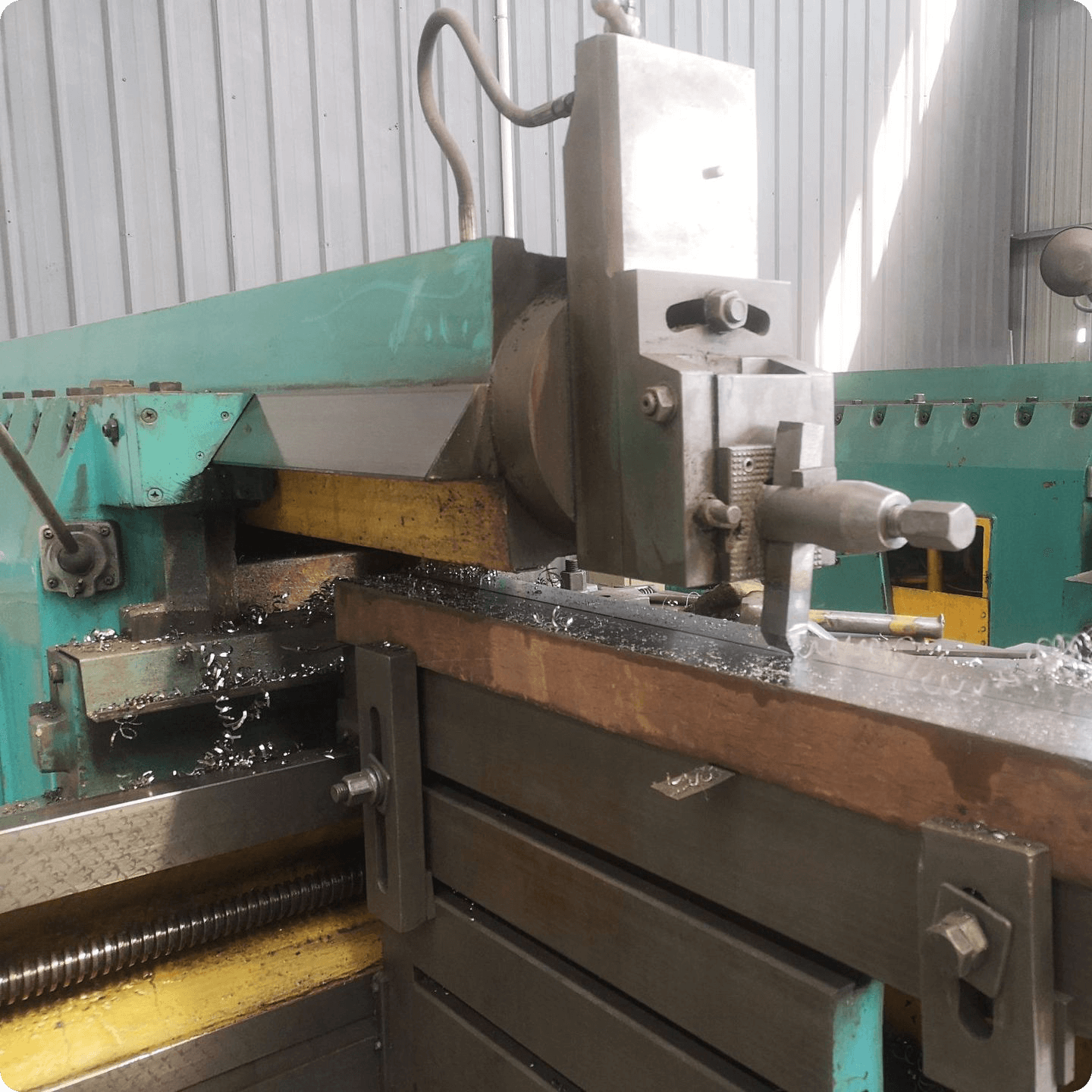

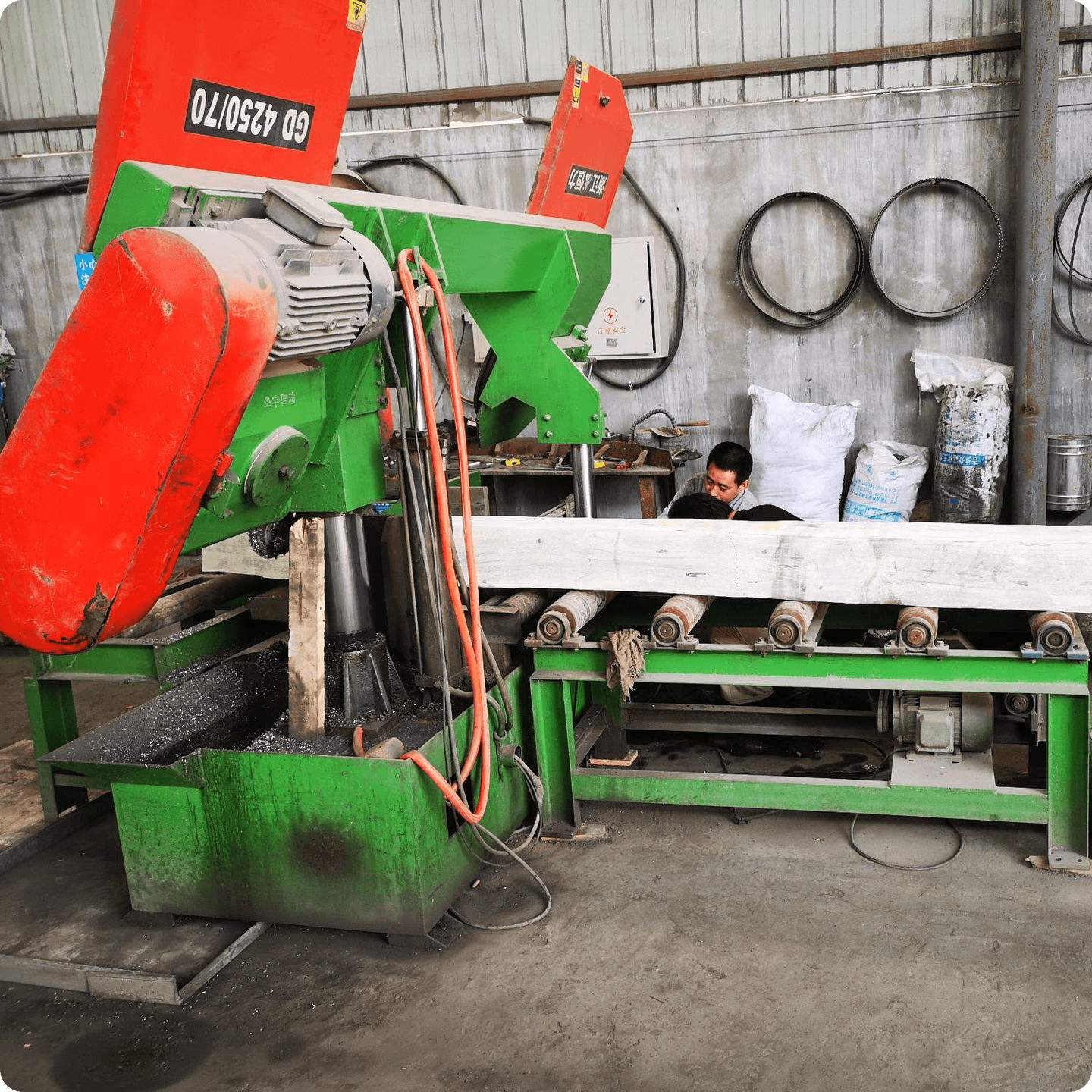

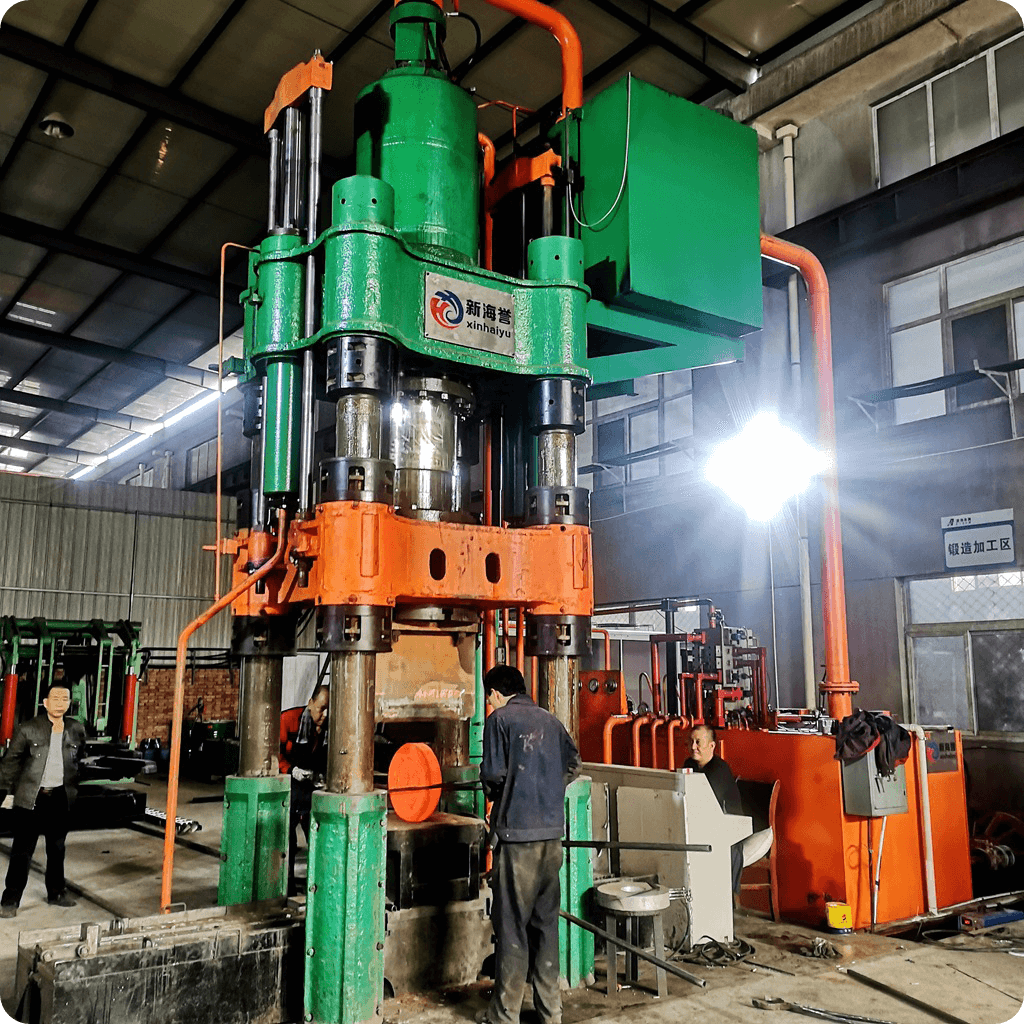

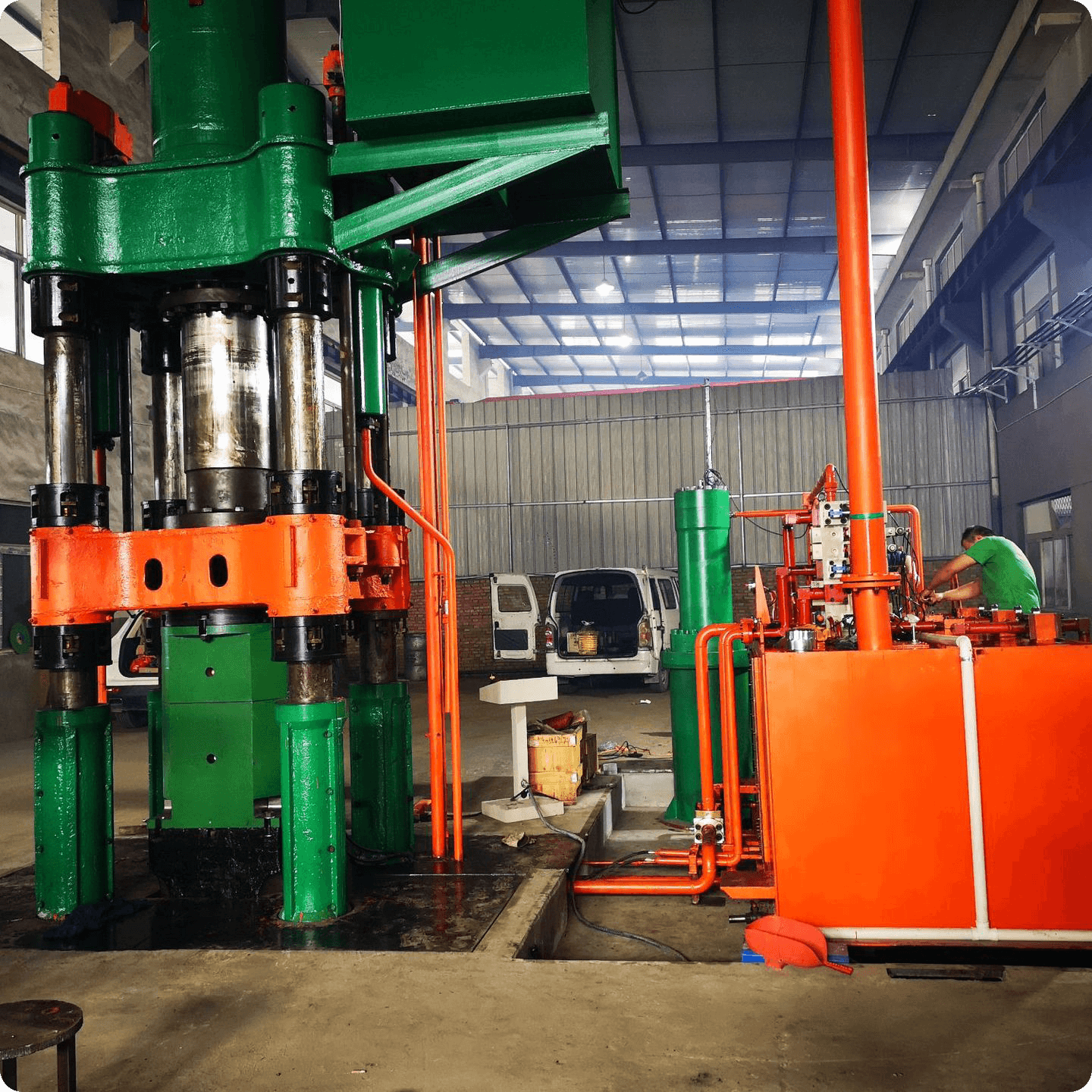

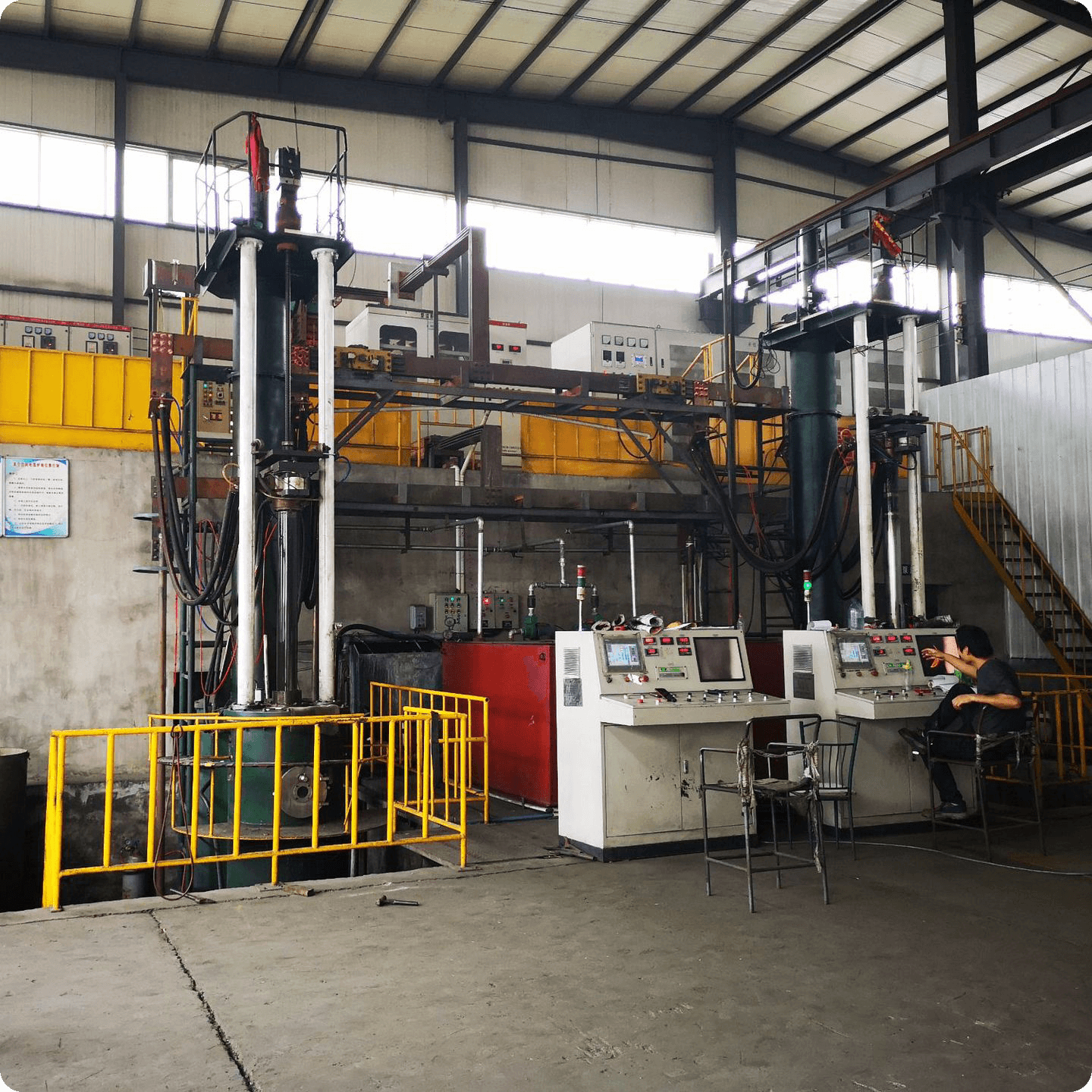

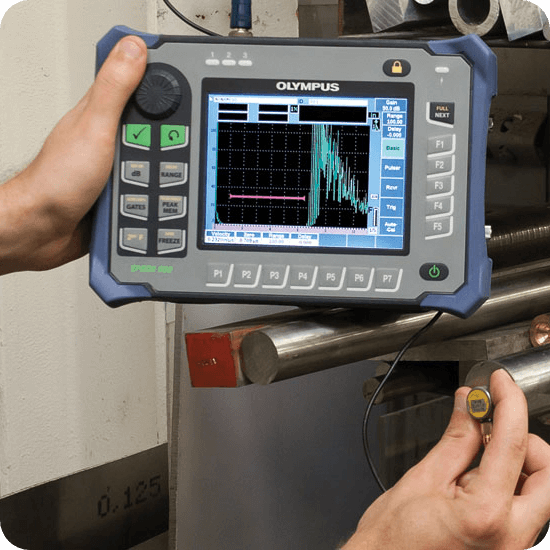

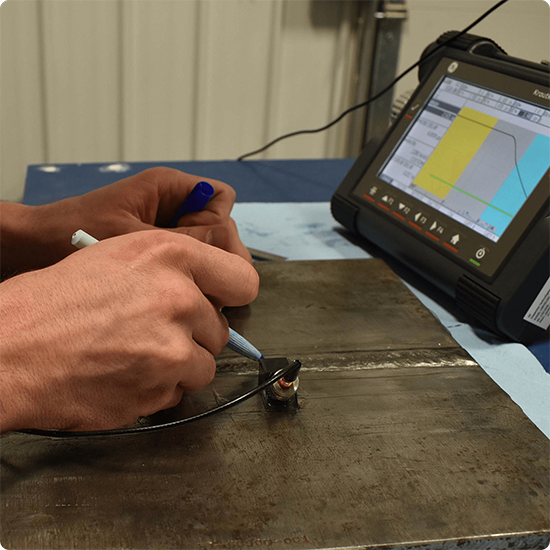

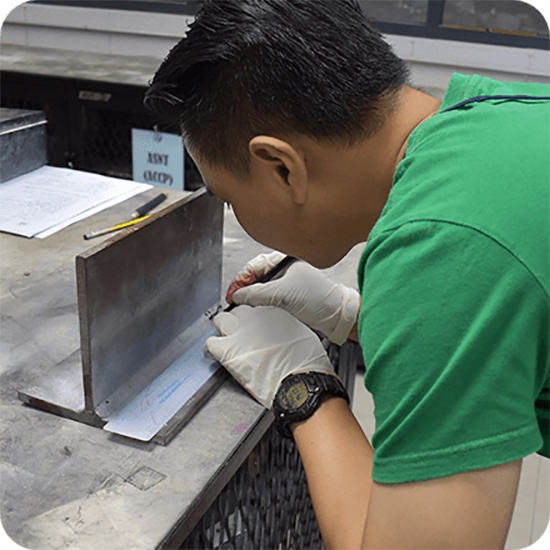

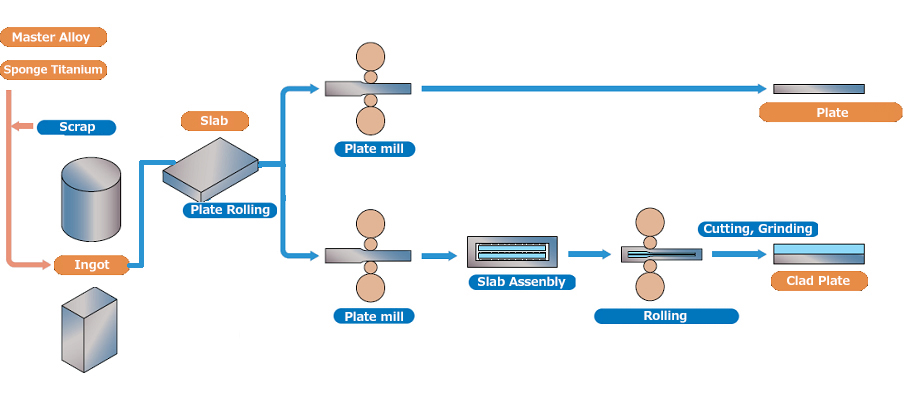

Here’s a simplified sequential explanation of the production process of titanium wire:

Here’s a simplified sequential explanation of the production process of titanium wire: