Corrosion, the invisible adversary, poses a constant threat to the integrity of metallic infrastructures. It introduces structural vulnerabilities, inflates maintenance costs, and raises serious safety concerns. These risks are notably amplified in harsh environments, such as the deep-sea abyss or when buried underground. In the face of such challenges, cathodic protection stands as a formidable shield, effectively safeguarding metal structures from the ravages of corrosion.

At the forefront of this defensive strategy is the anode, a crucial component that plays a pivotal role in the cathodic protection process. For industrial enterprises looking to fortify their assets with cathodic protection anodes, this guide provides a thorough insight, facilitating a well-informed and wise purchasing decision.

Table of Contents

Understanding Corrosion and Cathodic Protection

Corrosion is a natural process that deteriorates metal by converting it into its oxide, hydroxide, or sulfide form.

Cathodic protection (CP) is an electrochemical method to mitigate the corrosion of a metal surface, essentially by making it the cathode within an electrochemical cell setup. This is achieved by placing a sacrificial anode in proximity, which willingly corrodes, sparing the protected metal. The overarching benefits of CP span from prolonged operational life of metallic infrastructures, notable reduction in maintenance overheads, to upholding structural safety.

The Crucial Role of Anodes in Cathodic Protection

Anodes are indispensable in the cathodic protection strategy. They bear the brunt of corrosion, safeguarding the integrity of the protected structure. There are two primary types of anodes used in cathodic protection:

- Galvanic Anodes: These are made from metals that are more reactive than the structure being protected. Common materials include zinc, magnesium, and aluminum. They generate a protective current naturally, without the need for an external power source.

- Impressed Current Anodes: These anodes are usually composed of less reactive materials and require an external power source to drive the protective current. They are suitable for larger structures and provide greater control over the protective current.

Key Considerations for Selecting CP Anodes

a. Environment:

Different settings like saltwater, freshwater, or soil dictate anode choice. For instance, while zinc and aluminum are apt for saltwater, magnesium is ideal for soil and freshwater.

b. Current Requirement:

Determine the needed current as it affects both the anode size and quantity for optimal protection.

c. Anode Lifespan:

Galvanic anodes may deplete faster than impressed current anodes but don’t need external power, making them convenient in some scenarios.

d. Installation and Maintenance:

Choose anodes that simplify installation and require minimal maintenance. Consider the long-term implications, including the potential need for replacements.

e. Budget:

While quality is paramount, be aware of all costs: initial purchase, installation, upkeep, and replacement.

Selecting the right anode requires a balance between immediate needs and long-term considerations to ensure an efficient and economical protection system.

Key CP Anodes Manufacturers

Here’s a list of five prominent cathodic protection (CP) anode suppliers in the market, along with a brief description of each:

1. MATCOR Inc

Description: Established in the 1970s, MATCOR has emerged as a global frontrunner in the design and manufacture of corrosion prevention and cathodic protection products. Catering to industries ranging from oil & gas to utilities and construction, their product spectrum is diverse and reliable.

2. Farwest Corrosion Control Company

Description: With its roots dating back to 1956, Farwest stands as a comprehensive hub for cathodic protection and corrosion control-centric products. Their integrated approach, spanning design, distribution, and service, ensures a holistic strategy for combating corrosion.

3. Deepwater Corrosion Services Inc.

Description: Tailoring solutions for the unique challenges of offshore and sub-sea terrains, Deepwater Corrosion Services is renowned for its innovative cathodic protection paradigms. Their offerings are meticulously crafted to endure the rigors of deep-sea environments, championing both longevity and unwavering performance.

4. Cathodic Protection Co Limited (CPCL)

Description: Originating from the UK and backed by over six decades of industry presence, CPCL boasts a diverse portfolio of cathodic protection offerings. Their expertise gracefully traverses various sectors, right from the marine domain to expansive infrastructure projects.

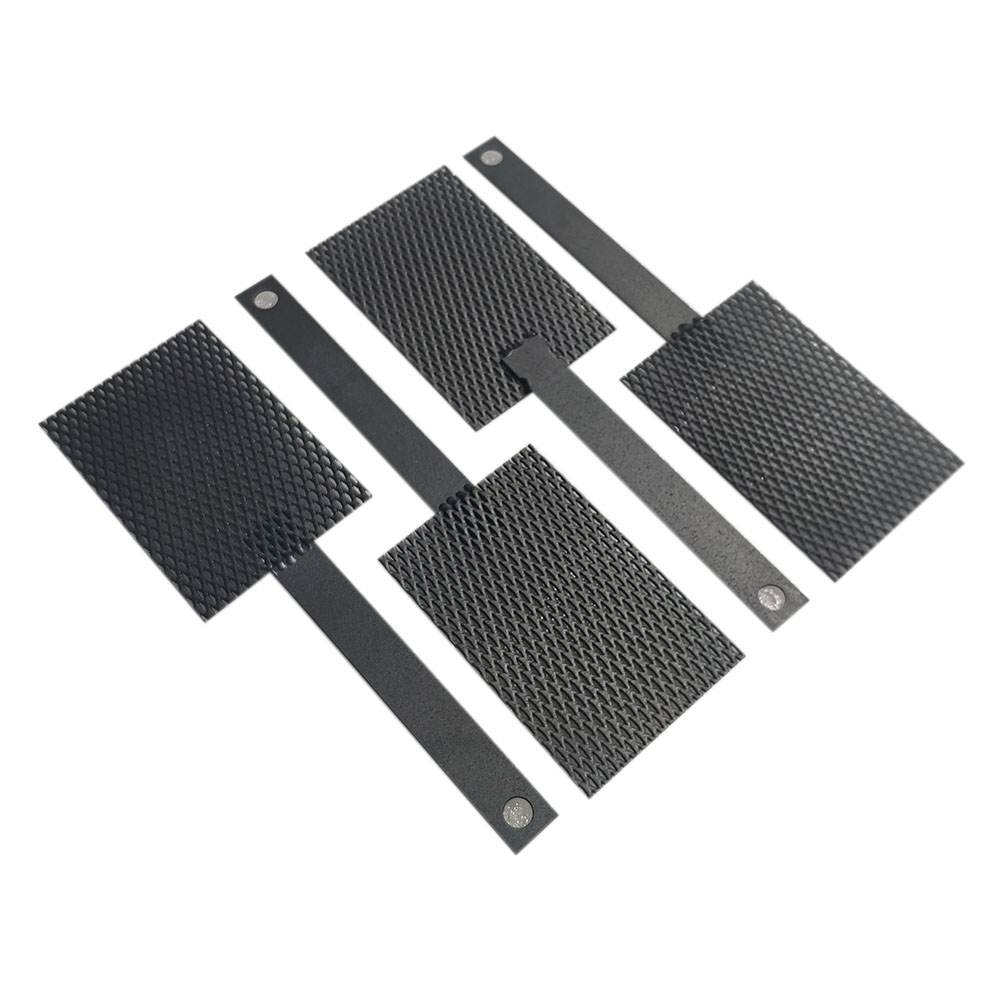

5. Hele Titanium

Description: As a stalwart in the realm of titanium manufacturing, Hele Titanium is revered for its high-grade cathodic protection anodes. With an emphasis on rigorous quality standards and state-of-the-art manufacturing processes, they offer titanium-based anodes that are both durable and efficient in various environmental conditions.

Conclusion

In environments prone to aggressive corrosion, cathodic protection emerges as a vital solution. The selection of the right anode is a critical decision that can significantly impact the efficacy of the protection. This guide serves to arm industrial enterprises with the knowledge needed to navigate these waters, ensuring a strategic, informed, and prudent investment in cathodic protection anodes, and ultimately, in the longevity and safety of their metallic infrastructures.